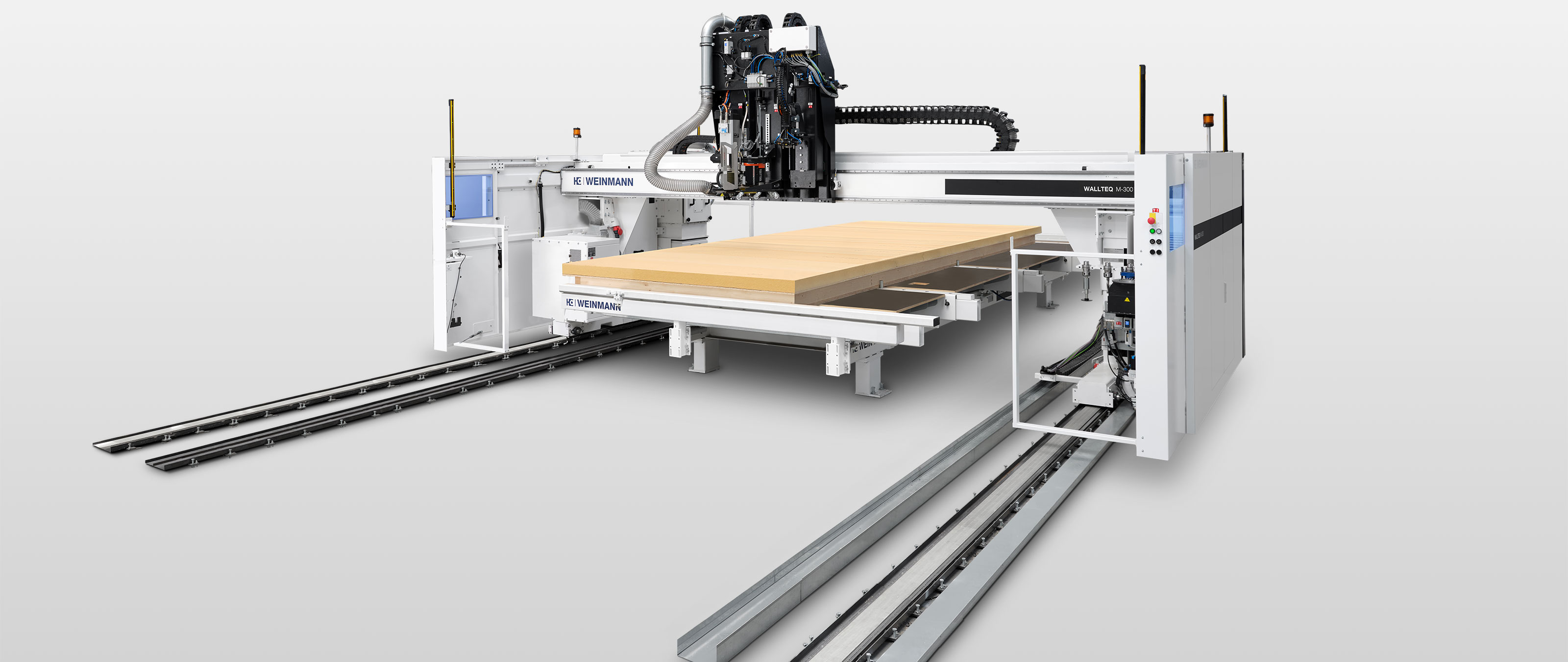

Multifunction bridge WALLTEQ M-300

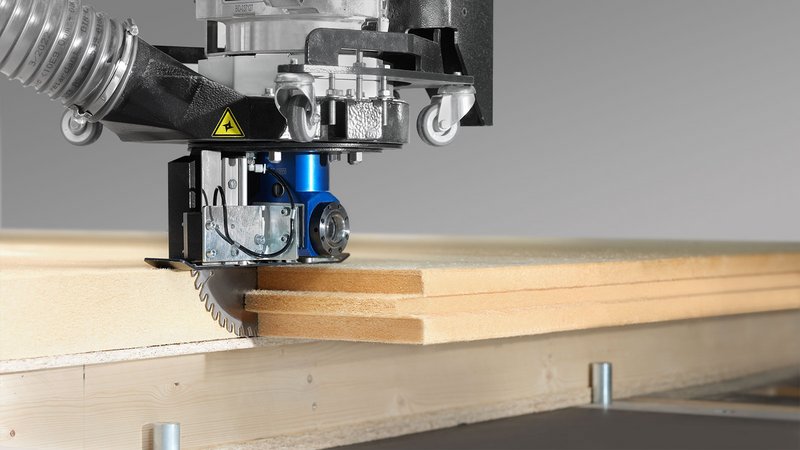

Spectacular sawing!

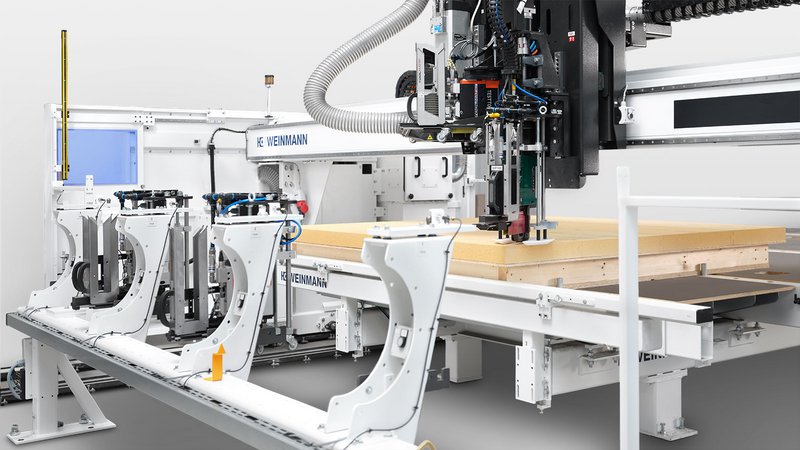

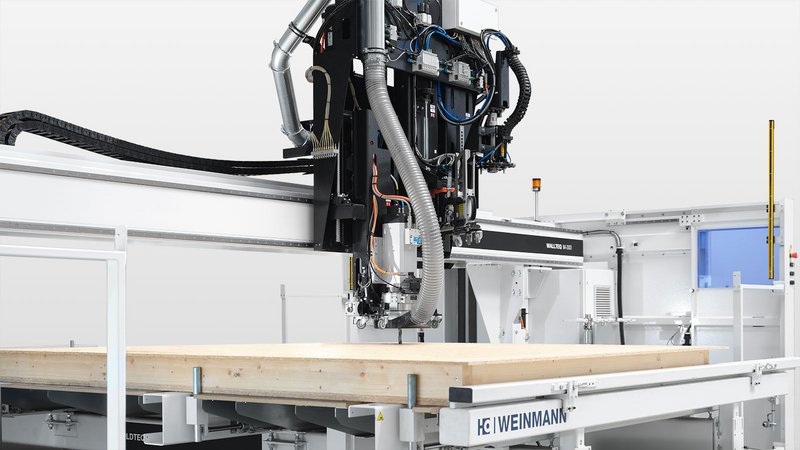

Your entry into the world of automation: the new WALLTEQ M-300 multifunction bridge. It was made to help your business move forward. The WALLTEQ M-300 can trim, saw (NEW!), staple, mark, nail and manufacture with the highest level of precision. It needs only minimal space, and the quick tool changer and clever functions make it even more flexible. The result speaks for itself. This is certainly the case on the construction site and even more so in your balance sheet: Expect up to 30% more productivity.

Benefits

The spindle of the WALLTEQ M-300 is equipped with a manual change function.

The large sawing tool with HSK chuck enables extremely precise processing of soft wood fiber insulation panels.

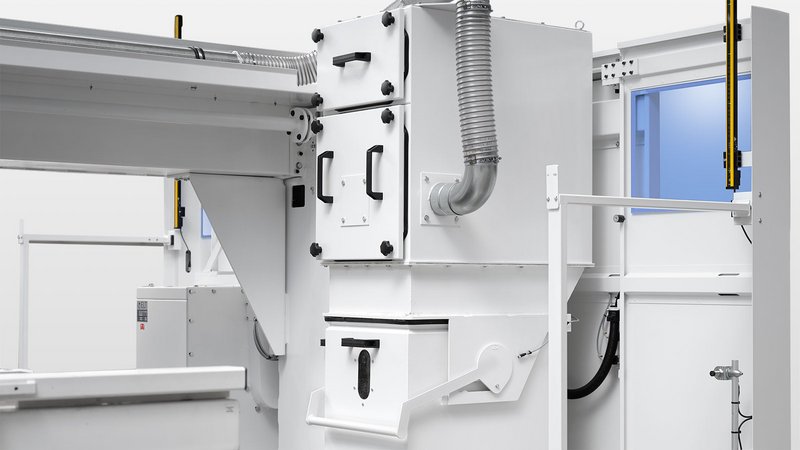

Perfect dust minimization: thanks to the compact deduster, you can process different materials comfortably.

With the optional fastenerSwitch, additional fastening units can be quickly inserted, which significantly increases the flexibility of the multifunction bridge.

With the high-performance trimmer, any cut-outs, such as socket holes, are child's play.

The marker can apply predefined drawings from the data record, which simplify further processing.

Sliding shoe for stapling and nailing devices enables material-friendly attachment.

Easy operation with the intuitive operation concept powerTouch

Features

13.2 kW spindle with manual change function between saw, marker and trimmer

Sawing unit for precise and fast processing with a cutting depth of up to 80 mm and saw protection with integrated suction technology

Fully automatic processing using a trimming unit with a depth of up to 90 mm and trimming protection with integrated suction technology

Improved piggyback suction device with a suction capacity of 2.2 kW and compact deduster

Suitable for use for wall elements as well as roof and floor elements

Existing work tables can be combined with the multifunction bridge

Can be integrated into a production line at any time

Optional: fastenerSwitch quick-change system for up to four fastening units in order to be able to react more flexibly to different types of fastenings and/or material

Optional: increased processing width to 3.80 m

Optional: swivel unit for fastening units for inclined insertion of fastening material; this is particularly in demand for narrow frame work designs (2x4 market)

Technical Data

| Processing depth | max. 80 [mm] |

| Piggyback suction device performance | 750 [m3/h] |

| Electrical connection | 15 [kW] |

| Compressed air consumption | approx. 500 [NI/min] during processing Approx. 1500 [NI/min] when fastening (depending on equipment) |

| Pneumatic pressure | 8 [bar] |

Technical information is subject to change!

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form