DRILLTEQ V-310 vertical CNC processing center

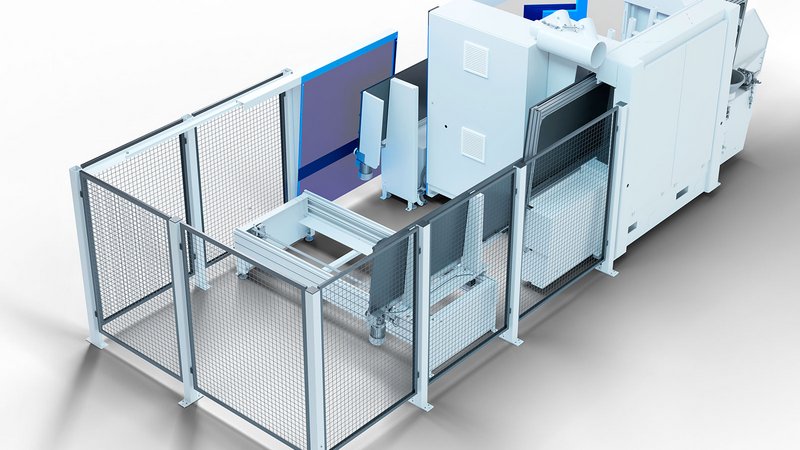

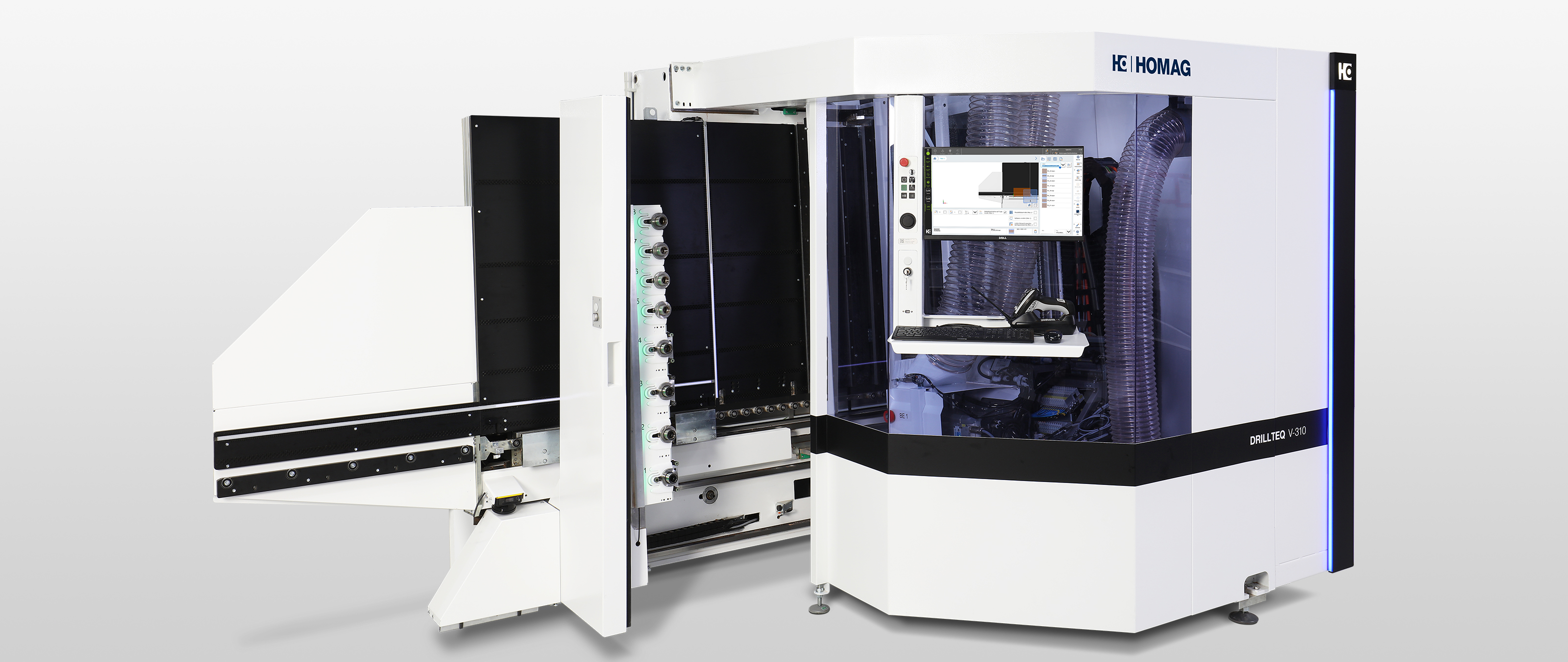

Maximum cabinet processing. Minimum space requirements. A space-saving miracle that requires just 11 m² of floor space.

The smart concept behind the DRILLTEQ V-310 offers as much functionality as possible in as small a space as possible. It makes optimum use of its 11 m², offering more drilling, more grooving and more trimming than any other machine in this design class. It is even possible to process doors, as well as every type of connector used in furniture construction. Optimize your workpiece handling and tool change handling with intelliGuide LED operator assistance, and look forward to ergonomic processing thanks to the swiveling control unit and the height-adjustable monitor.

Benefits

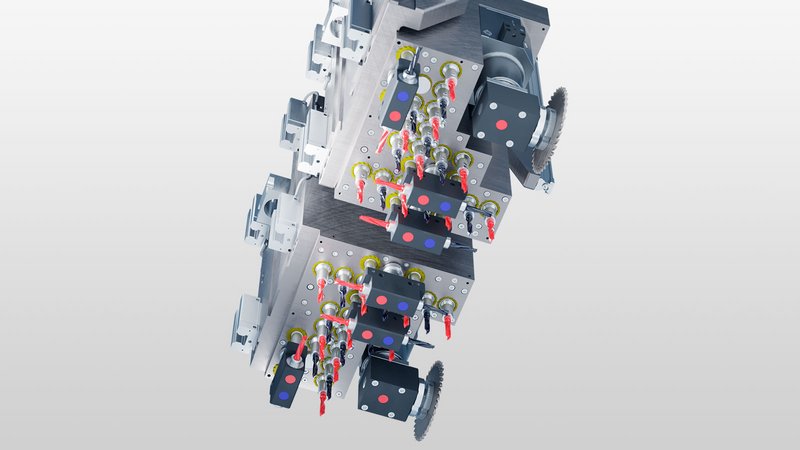

Split-head drilling gear to enable simultaneous processing of mirror-image workpieces.

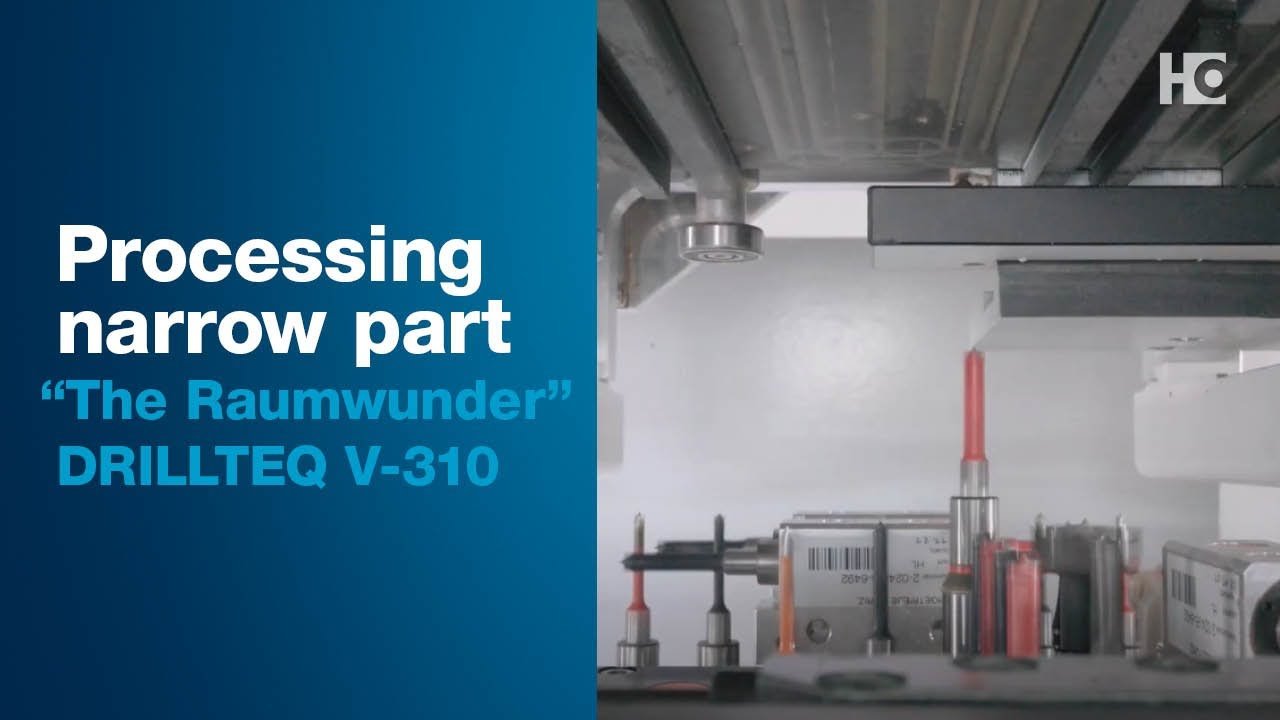

The tool changer on the inside of the access door offers eight slots.

The intelliGuide optical LED assistance system specifies the slot assignment when the tool is changed.

Swiveling control unit with height-adjustable monitor for ergonomic operation.

The intelliGuide optical LED assistance system shows the workpiece sizes and also the correct positioning for insertion into the machine.

Automatic return to save time and provide ergonomic relief for the operator.

Dowel technology for automatic insertion into the defined positions including variable drive-in depths.

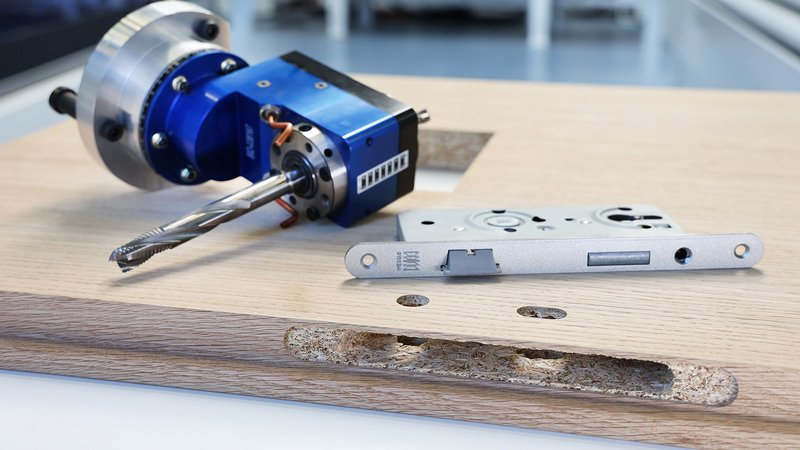

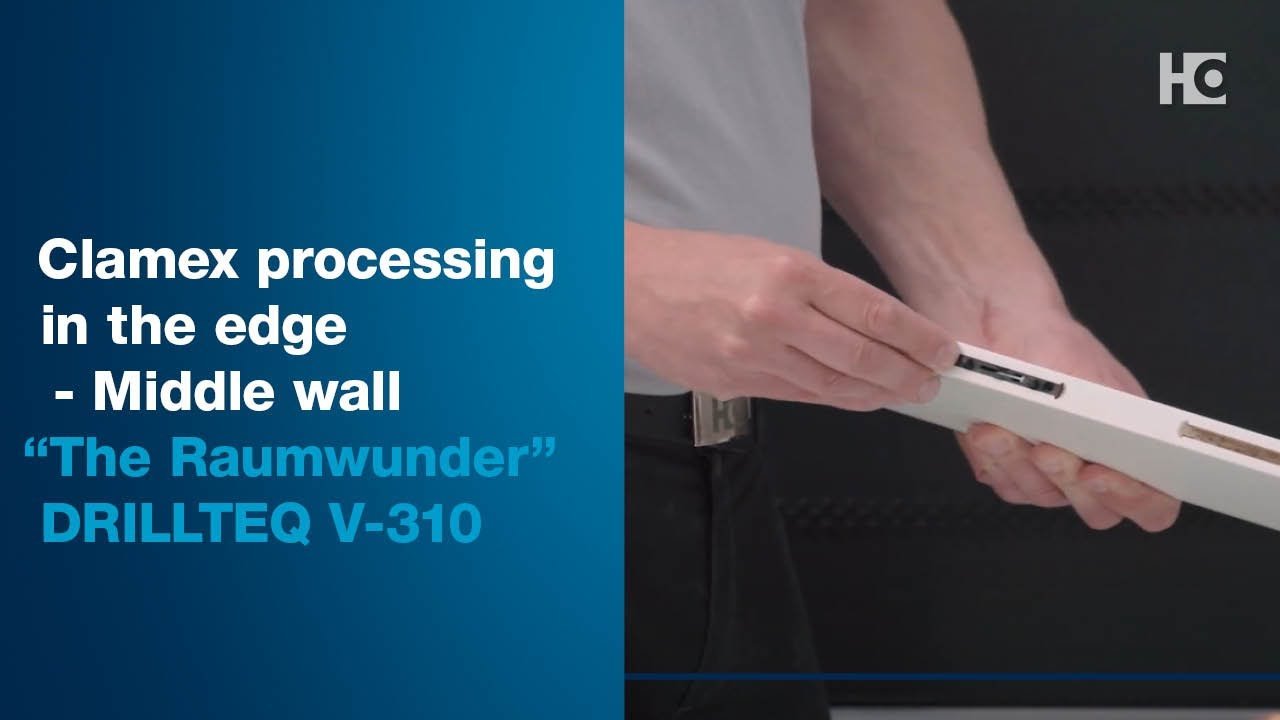

Whether classic trimming and drilling or the production of pockets, there are no limits to the choice of furniture connectors.

Room doors will soon be fully manufactured with rabbet processing, lock casing, Anuba belts or cut-outs for glass panes, including corner notching.

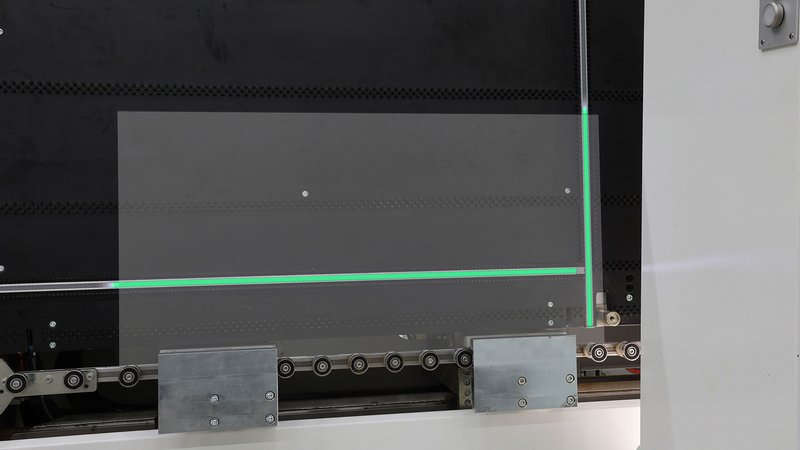

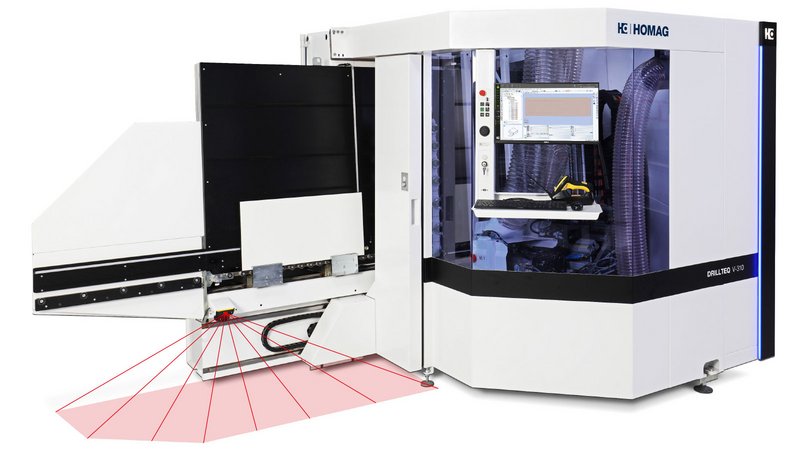

safeScan safety concept. Invisible check by means of a scanner at the machine infeed and outfeed.

Features

8-slot tool changer

5° gravity-based tilting for easier workpiece handling

intelliGuide LED assistance system

Foot switching strip for easy workpiece clamping

Plausibility check and workpiece measuring to safeguard processes

Complete door processing

safeScan — safety concept for optimum and safe interaction between man and machine

Swiveling control unit with keyboard tray, height-adjustable monitor and powerTouch operating concept

Barcode scanner to quickly access and read programs and requirements

Workpiece return to increase efficiency and optimize processes

Technical Data

| Workpiece length [mm] | 200 – 3,050 |

| Workpiece width [mm] | 50 – 1,250 |

| Workpiece thickness [mm] | 8 – 80 |

| Total machine weight [kg] | ca. 3,600 |

| Installation dimensions L x W x H [mm] | 5,300 x 2,260 x 2,160 |

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form