Carpentry Machine BEAMTEQ B-660

All six sides of a component in a single run

Benefitting from an underfloor unit, the BEAMTEQ B-660 from WEINMANN enables fully automated processing of all six sides of a component. Quickly and easily manufacture traditional block house joints, blocking grooves on rafters and dovetail connections on both sides of ridge beams.

(Carpentry Machine WBZ 160 powerSIX)

Benefits

The carpentry machine can be optimal positioned in the production hall.

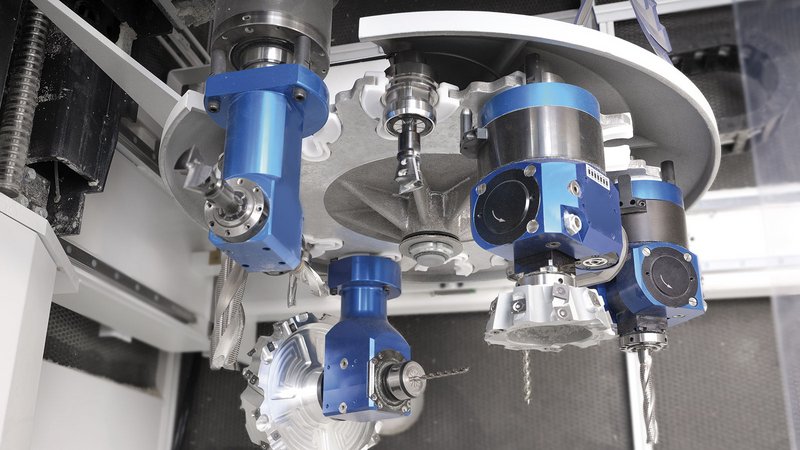

12-fold tool changer can be individually equipped

Production of a groove

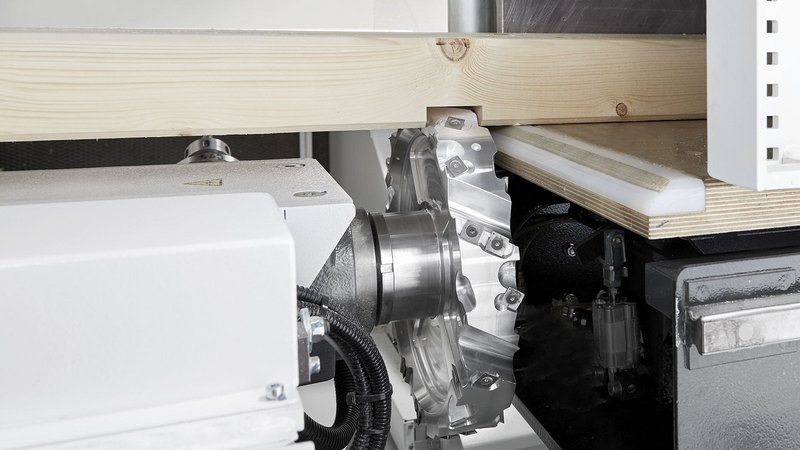

Fully-automated 6-side-processing with the underfloor unit

Routing processing with the underfloor unit

Labelling and marking with the ballpoint pen

Production of hip rafter notch

Automatic removal for strands and off cuts removal by the Ascending conveyor

Features

The underfloor unit: Features a 6.6-kW side milling cutter plus a 7.5-kW drive unit for a finger trimmer, dovetail trimmer or drill

12-slot tool changer and second integrated main spindles

5-axis technology for trimming, sawing and drilling

Reduced noise and dust emissions thanks to the fully enclosed machine housing

FLEX5 sawing unit: A rotation angle of 0–360° in conjunction with a swivel angle of 0–90° allow you to process angled cuts, notches, rafter assembly cuts and rip cuts

High level of processing accuracy thanks to the NC gripper system combined with vertical and horizontal clamps

Technical Data

| Min. cross-section | 20 x 50 [mm] |

| Max. cross-section | 200 x 455 [mm] |

| Min. unprocessed timber length | 1,500 [mm] |

| Max. unprocessed timber length with intervention | 16.5 [m] |

All technical data are without engagement!

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form