Panel dividing saw SAWTEQ S-320 flexTec

Its advantages in batch size 1 production: individual cutting, fully automated production processes, unlimited recuts.

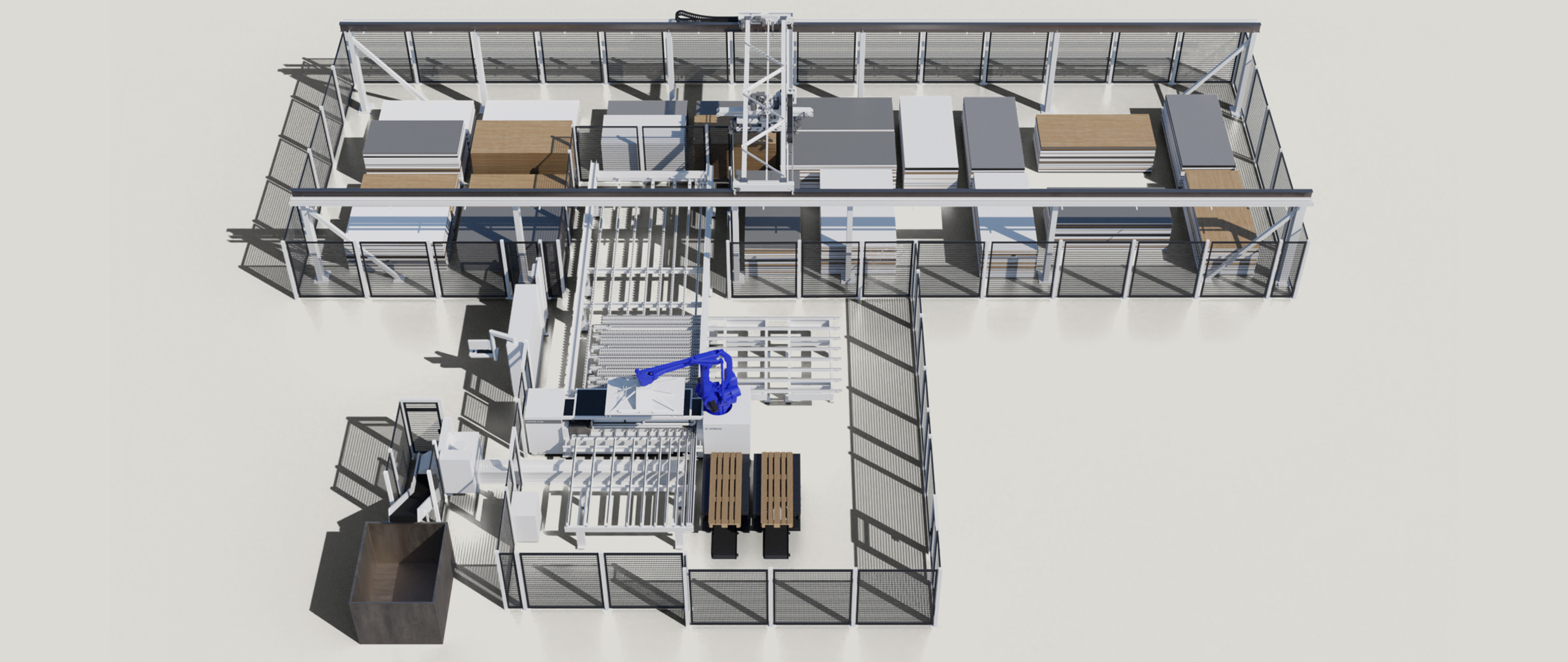

The SAWTEQ S-320 flexTec is a revolutionary cutting cell to custom cut single panels. This innovation is based on a concept that totally redefines the parts flow in order-based production and allows single panels to be custom cut under batch production conditions.

(Panel dividing saw SAWTEQ B-320 | HPS 320 flexTec)

Benefits

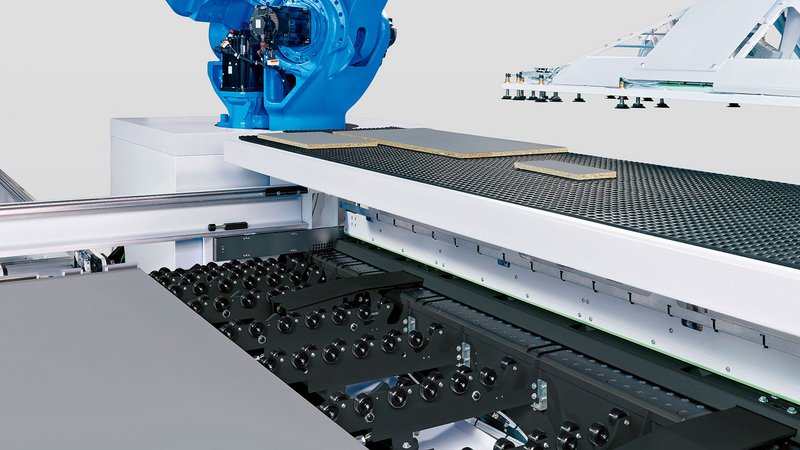

Active strip buffer: the robot deposits the strips here. Subsequently, they are automatically fed to the rear machinetable.

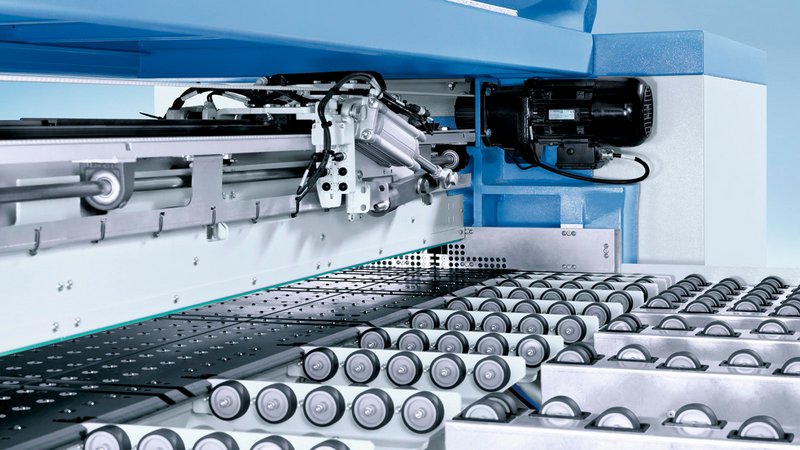

Robust clamps automatically position the panels on the cutting line.

dustEx combination air jets guide dust and chips straight to the extraction system at the right-angled fence.

The rear machinetable features lengthwise and crosswise alignment and roller rails for material-friendly transport.

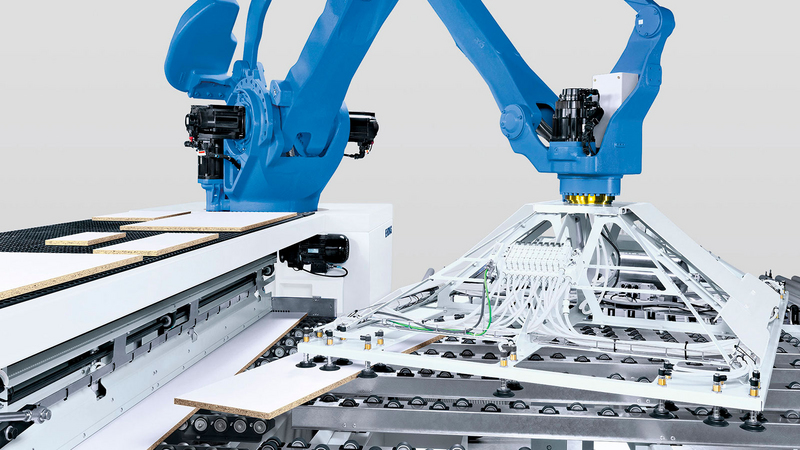

The robot deposits parts on the outfeed with fully automatic labeling – correctly oriented for subsequent processing. (Option)

Lengthwise and crosswise alignment: panels from the store arrive here; the robot places parts to be recuts here; and strips are moved here from the machinetable.

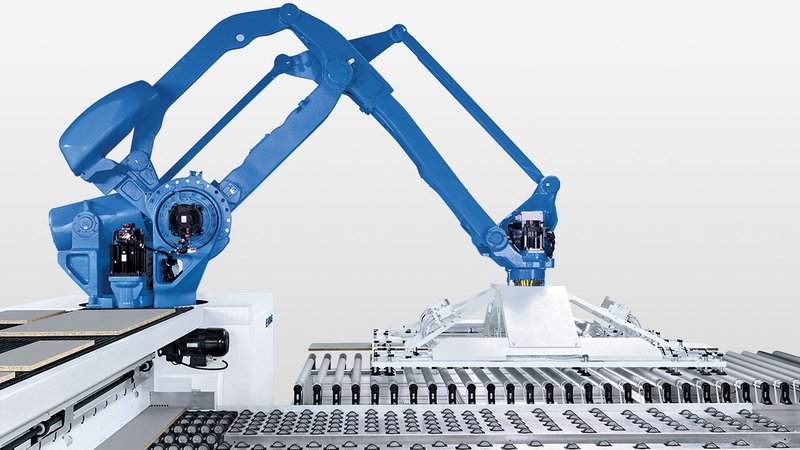

The robot with suction traverse deals with the handling of panels, strips and parts – automatically, flexibly, accurately and efficiently.

Parts buffer for recuts – the robot temporarily stores certain parts here.

The cutting direction is towards the right-angled fence. This prevents the panels from shifting and optimizes extraction.

Innovative program fence for lasting precision, low maintenance requirements, material-friendly handling and maximum availability.

Features

The industrial robot undertakes all the panel handling

The automatic ejecting device transports all the parts away from the cutting line and back into the work area of the robot

Software-controlled waste flap – opens and closes in sync with the machine

An automatic labeling system labels all the finished parts

All parts leave the saw in the correct orientation

Technical Data

| Saw blade projection | 58 [mm] |

| Cutting length | 3,200/4,300 [mm] |

| Panel dimensions | max. 3,150 x 2,200 mm for 3,200 mm cutting length max. 4 300 x 2 200 [mm] for 4,300 mm cutting length |

| Part size | max. 2,400 x 1,200 mm / min. 240 x 80 [mm] |

| Saw carriage speed | up to 150 [m/min] |

| Program fence speed | up to 90 [m/min] |

| Main saw motor | 5.5 [kW] |

| Operating software | CADmatic 5 |

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form