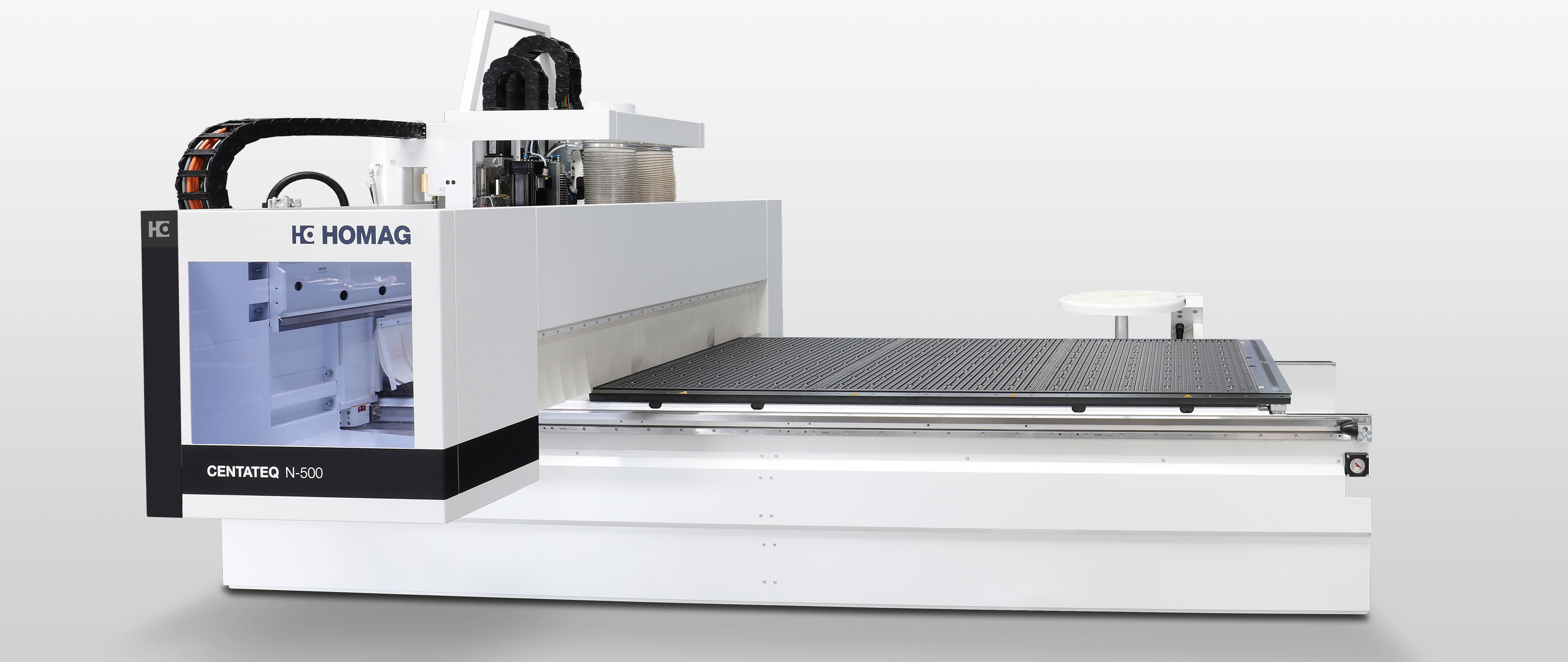

CNC Gantry-Processing Center CENTATEQ N-500

The compact nesting machine in gantry design

Our nesting machines enable cutting-optimized processing and dividing of plate-shaped materials. The typical applications of nesting are creation of carcass furniture, dividing and refining of furniture fronts and construction of frame furniture. Various possibilities for the automation of the material handling ensure a high time saving and an even more effective work.

(CNC Gantry-Processing Center Vantage 100)

Benefits

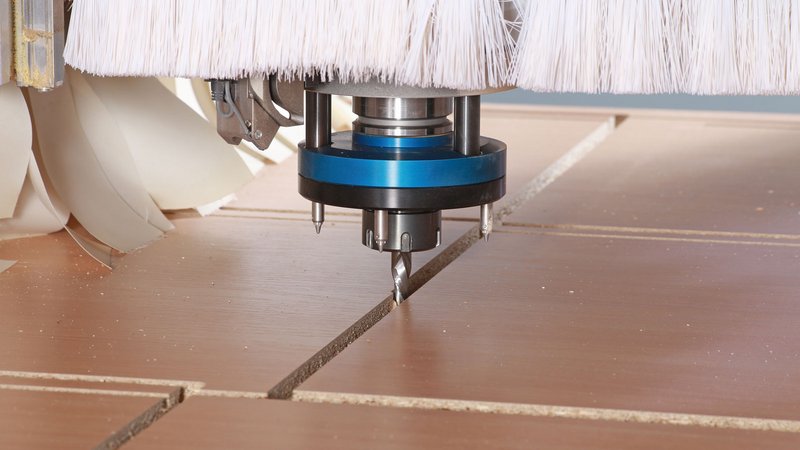

Panel dividing by nesting procedure

MATRIX table with vacuum cups for extended processing freedom

Configuration: 12 HP (9 kW) HSK routing spindle

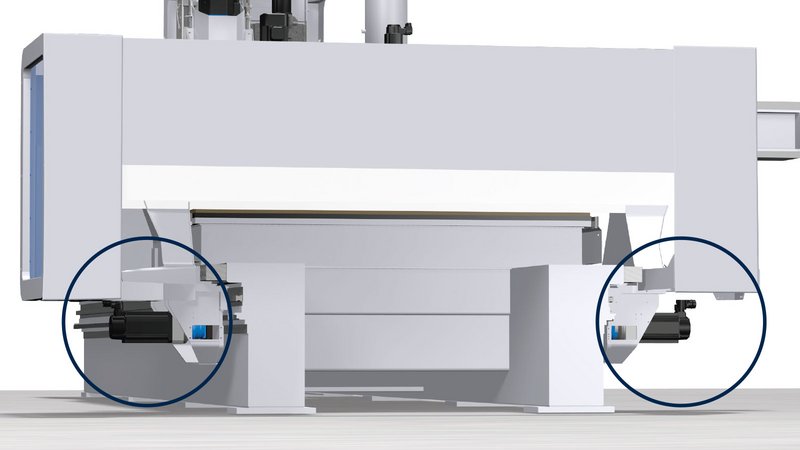

2 synchronised digital servo-drives in X-direction guarantee highest processing quality

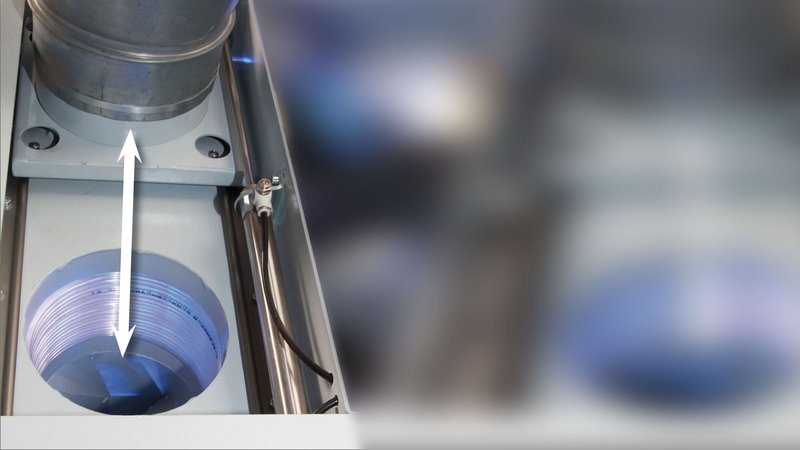

Program-controlled extraction connection for an optimum extraction behavior and economic use of energy (ecoPlus)

Tool changing system with 7, 8, 10 or 12 places depending on working field

Infeed- and push-off function for workpieces

Tool changing system with 14, 28 or 42 places availablle

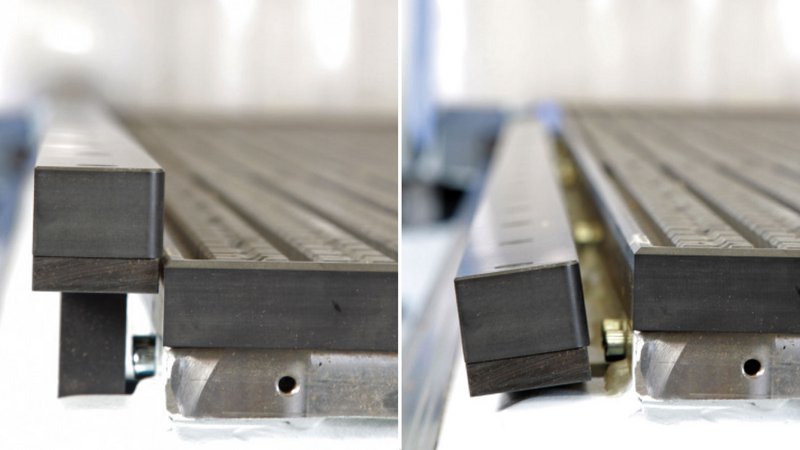

Lowerable fence guide for safe outfeed of workpieces

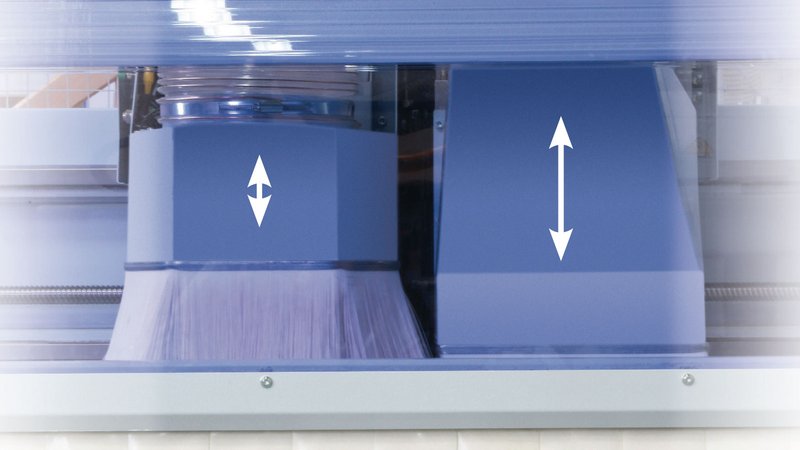

2 CNC-controlled Z-axes for more stability and higher processing quality

Features

The whole working field is reachable with all processing tools

Electronic surveillence of all stops

Efficient use of energy through high vacuum performances and simultaneously minor power consumption

12 HP (9 kW) HSK routing spindle (optionally: 16 HP (12 kW))

Tool changing system with 7 to 12 places depending on working field size

Software bundle for machine and PC (option)

Technical Data

| CENTATEQ N-500 | 480 | 510 | 512 | 612 | 710 | 714 |

|---|---|---|---|---|---|---|

| Working field width [mm | ft] | 1250 | 4 | 1550 | 5 | 1550 | 5 | 1850 | 6 | 2250 | 7 | 2250 | 7 |

| Working field length [mm | ft] | 2520 | 8 | 3100 | 10 | 3700 | 12 | 3700 | 12 | 3100 | 10 | 4300| 14 |

| Working field height [mm | inch] | 100 | 3,94 | 100 | 3,94 | 100 | 3,94 | 100 | 3,94 | 100 | 3,94 | 100 | 3,94 |

| Vacuum capacity [m³/h] [Hz] | 290/345 50/60 | 580/690 50/60 | 580/690 50/60 | 580/690 50/60 | 870/1035 50/60 | 870/1035 50/60 |

Technical information is subject to change.

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form