CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-500

Drilling and dowelling – and always keeping a tight grip on everything

Whether as individual machine or complementary product in connection with a CNC processing center – the DRILLTEQ D-500 has two tasks: drilling and dowelling – making the machine more efficient and reliable than ever before. Space-saving complementary products for clever support in your company.

(CNC-Drilling and Dowel Inserting Machine ABD 260)

Benefits

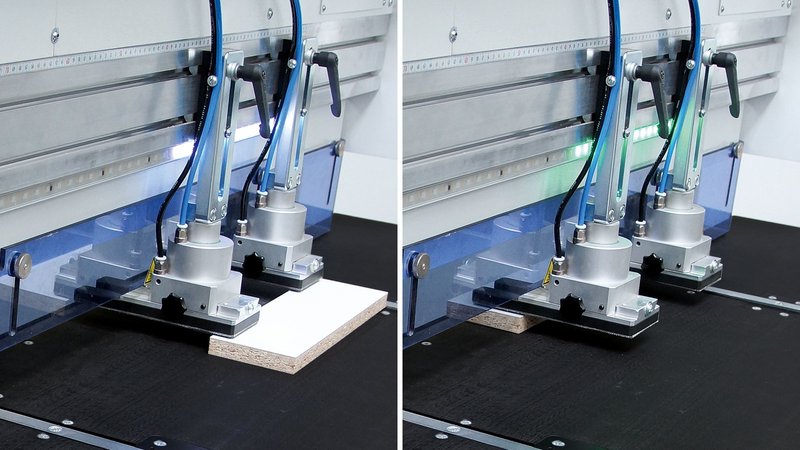

Optical LED assistance system intelliGuide Classic (optional)

Center stop for flexible handling of workpieces

Lateral stop pneumatically lowerabler

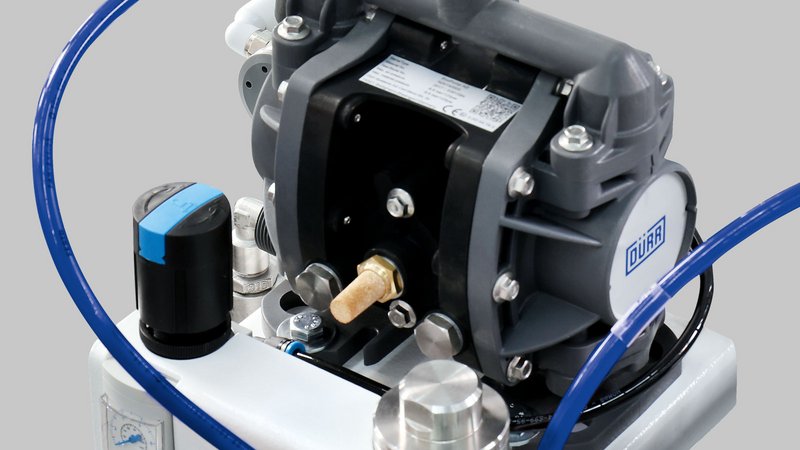

Low-pressure glue pump

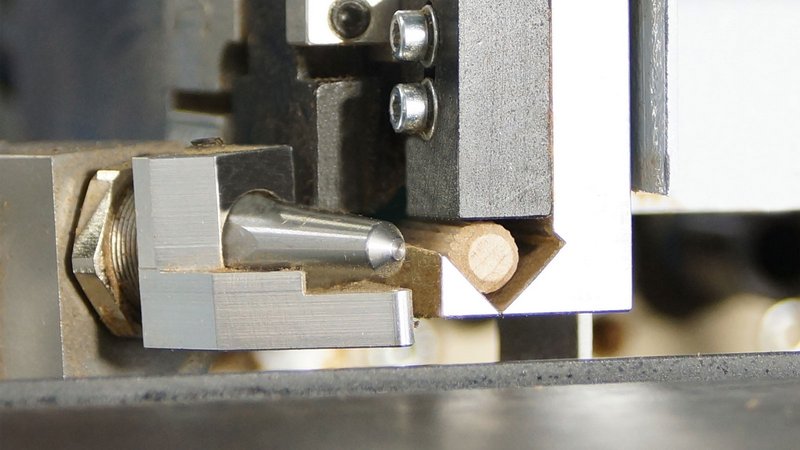

Dowelling tool with glue application

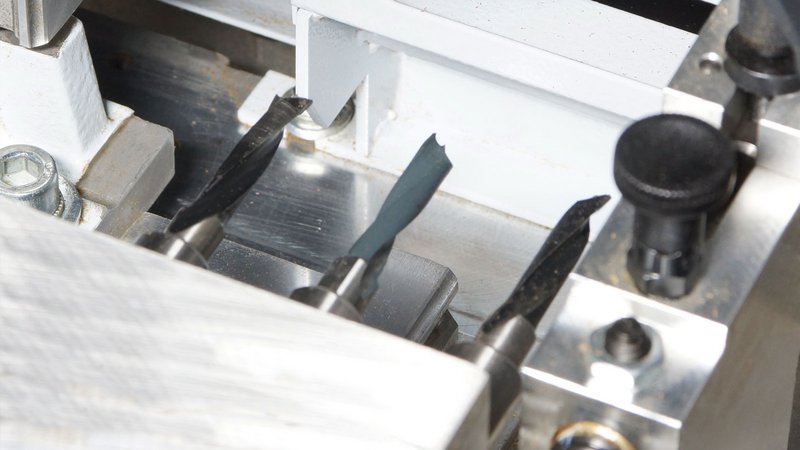

3 vertical drilling spindles

3 horizontal drilling spindles

Vibrating conveyor

woodWOP – 3D-presentations of all relevant elements

Features

Improved ease of use and error prevention while positioning workpieces by the optical LED assistance system intelliGuide Basic (optional)

The lowerable center stop allows for flexible handling of workpieces

Space allocation for up to 4 workpieces

Precise machining for horizontal drilling and dowelling with 3 individually selectable drilling spindles with 32 mm pitch

3 Individually selectable vertical drilling spindles with 32 mm pitch for diverse drill diameters up to 35 mm

Pneumatically lowerabler lateral stop with manual control by (selection) switch

Low-noise level and compact low-pressure glue pump

Dowelling tool with adjustable glue amount and glue flow control

Automatic and reliable feed of standard dowels by vibrating conveyor

Technical Data

| DRILLTEQ D-500 | Model 1 + 3 | Model 2 + 4 |

|---|---|---|

| Workpiece length[mm] | 20 – 1.250 | 20 – 2.800 |

| Workpiece width[mm] | 20 – 800 | 20 – 800 |

| Workpiece thickness[mm] | 10 – 80 | 10 – 80 |

| Compressed air connection [inch] | R 1/2“ | R 1/2“ |

| Compressed air [bar] | min. 7 | min. 7 |

| Total connected voltage [kW] | approx. 7 | approx. 7 |

| Extraction connection [mm] | Ø 80 | Ø 80 |

| Total machine weight [kg] | approx. 1.600 | approx. 2.200 |

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form