HOMAG INTELLIGENCE: The digital, modular platform for sales, configuration and production

Seamless processes from furniture sales to furniture production

When it comes to the ongoing digitalization and management of data throughout the order and production process, wood processing companies of all sizes are currently facing a number of questions:

- How do I transfer data from one software to the next and achieve continuous data usage?

- How can I reduce the growing effort for data management (master data)?

- What options are available for presenting my products in an attractive way during the sales process?

- Which software modules are right for my product portfolio and how do they integrate into my overall process?

The starting point for these questions is similar for almost all companies — regardless of the size of the company or the end products. Today, companies can access a wide range of software tools on the market throughout the entire process chain—from the design and sale of furniture to production/delivery—each with different data and in different application areas.

For example, there are online configurators for the design of the desired furniture, planning software for the sales consultant in the furniture store or order entry and design programs (CAD/CAM) for work preparation. All of these software tools generate planning, design or order data that needs to be reused in industry solutions or ERP systems or passed on to production. Until now, there was no solution available on the market for end-to-end networking of all data from the point of sale to the completion of the furniture in production. Data had to be transferred to different software systems manually and be managed several times, or individual interfaces had to be programmed with great effort.

From now on, however, these processes can be seamlessly linked to each other:

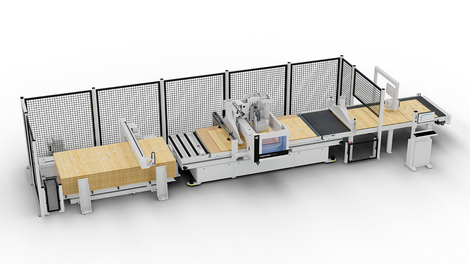

With HOMAG INTELLIGENCE, the first solution on the market has been developed that creates an end-to-end network of the processes in furniture sales and furniture production. More precisely, HOMAG does not offer individual software here, but an open platform, which seamlessly connects all data resulting from the sale of furniture, the design and creation of order and production data, through to production and interaction with the machines with central cloud-based data — regardless of the machine pool, the existing software landscape or the size of the furniture manufacturer's business.

On one hand, this is provided by central data storage throughout these processes. On the other hand, individual digital components (software products, apps) with open interfaces ensure that the central data storage is fully integrated into an existing software landscape, therefore guaranteeing a continuous flow of data without interruptions. The result is centralized, transparent data management throughout the individual process chain of the operation, regardless of which software systems are currently in use. In other words, a consolidated and efficiently organized process — from start to finish.

Coordinated interfaces have been lacking — until now

The integrated data flow throughout the entire process chain is one major advantage of the HOMAG INTELLIGENCE platform. Up to now, there has only been one option for transferring different file formats from one software to the next: individually programmed interfaces. The furniture manufacturer usually acts as a mediator between various software providers and bears the often high manual and financial costs. The result is often a complex order and production process, which is partly redundant and prone to errors and which requires experts to manage. HOMAG INTELLIGENCE is the first solution on the market to establish a continuous flow of data between all furniture production processes — from sales to design and the creation of order and production data right through to production directly on the machines.

Say goodbye to duplicate data management: Enter once, available everywhere, always up-to-date

Today, the manual maintenance of product catalogs and the associated master data is becoming increasingly complex. Custom and newly conceived furniture designs must be created, while the products from our own portfolio must be maintained and kept up-to-date. The same applies to material catalogs from different manufacturers or the fixture range. HOMAG INTELLIGENCE ensures that the effort required for data management is reduced and kept to a minimum. One advantage of the platform is that the user has access to all relevant sales and design data with just one login. This provides a clear overview of data throughout the entire process at a glance and the sales and design data is used along the entire process chain. When data is updated in a software tool, the update is performed automatically in all other systems — without redundant data entry and maintenance.

Design without errors thanks to predefined libraries

A lot of time is also lost when designing the furniture. At the same time, errors can creep in. To ensure that this does not happen, HOMAG INTELLIGENCE offers the right solution with newly developed, tested "design libraries". These are predefined basic libraries for furniture configuration that can be adapted and extended at the same time, and are automatically supplied by HOMAG INTELLIGENCE. They contain the common principles according to which a piece of furniture can be constructed. As soon as new market trends occur in the industry, HOMAG updates the pre-conceived designs accordingly. The furniture manufacturer can customize the libraries according to their own preferences and, if necessary, expand them individually without losing the ability to update. This allows existing and future furniture to be mapped while ensuring error-free design — and this within a considerably reduced amount of time.

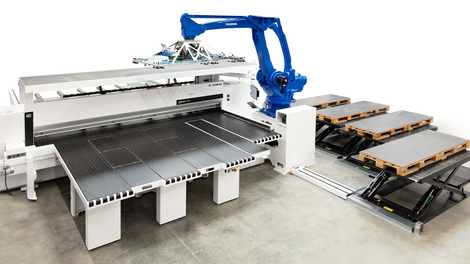

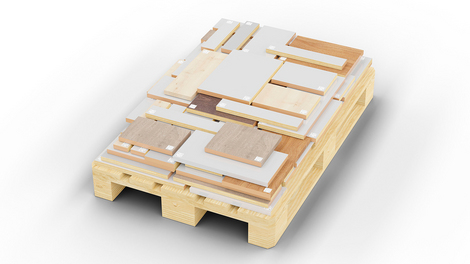

Flexible in production: Distributing orders to different plants

Anyone who manufactures at different locations or works together with partners will be able to control orders in an agile manner via the cloud in the future. With HOMAG INTELLIGENCE, furniture manufacturers can easily distribute orders to their own (regional) production facilities or to partners at the push of a button, thus transferring capacities. This creates the freedom to flexibly cope with fluctuating capacity utilization at the plants or to switch to production at a site near the end customer in the interests of sustainability, for example.

Scaling without risk: The platform can be expanded in a modular way

Choosing HOMAG INTELLIGENCE means avoiding investment risks. HOMAG INTELLIGENCE provides various packages, modules and open software systems that can be individually combined. The platform can be expanded as required with additional packages or modules — and it grows with the requirements of the furniture manufacturer. The majority of the digital components do not need to be installed, can be easily used in the browser and can be terminated annually. This eliminates the need for expensive investments in a server landscape and their maintenance and servicing. Another advantage is that the functionality of HOMAG INTELLIGENCE can be expanded step by step and adapted to any size of company. HOMAG INTELLIGENCE is also opening up new possibilities when booking products — for example, volume-based billing (based on the number of parts) will be possible in the future.

The advantages and functions of HOMAG INTELLIGENCE can be expanded step by step and adapted to any size of company. All of this works regardless of which suppliers have provided the software products used so far in the company or whether machines from other manufacturers are integrated in the machine pool. The HOMAG INTELLIGENCE platform is the solid backbone of it all and acts as the central basis for cloud-based data processing and forwarding to various software systems, process steps and machines.

All advantages of HOMAG INTELLIGENCE at a glance

- One platform for all processes from sales to production:

Smooth mapping and seamless networking of furniture sales and furniture production processes. - End-to-end networking of all data:

Continuous data flow from the configuration in the sales process to order management in work preparation and handling material and order data in production. - Transparent data without duplicate data management:

All relevant sales and design data throughout the entire process in one place, with one login — automatically updated without redundant data entry. - Flexible and error-free design:

Libraries (with predefined, tested design elements) for error-free designs. - Flexible in production:

Simple and agile order control via own production, suppliers or partner networks. - Open interfaces:

Whether single module or complete solution: Seamless integration thanks to open and coordinated interfaces in every existing software landscape and machine pool — also in conjunction with third-party machines. - Scaling without risk:

Step-by-step expansion of the solution with cloud-based modules with low investment risk — from individual machines to extensive machine pools. - State-of-the-art technology:

Be ready for the future by using the latest technologies as a basis (central data storage in the cloud, AI). - Fit for the future:

Export current data for various analyses (machine, production, order and master data) through central data management in the cloud via an interface. - Easy to use:

Intuitive operation and coordinated interfaces (plug-and-play) reduce the time-consuming training and deployment of skilled staff.

HOMAG INTELLIGENCE vs. tapio: Two platforms, various tasks

Anyone who uses apps and digital assistants from HOMAG has already come into contact with the tapio platform. The reason HOMAG has now launched another platform is based on the different purposes for which the two platforms are used.

tapio is a digital infrastructure that is accessible to the entire industry. tapio offers this infrastructure to both HOMAG and the now more than 45 partners from the wood industry and furniture manufacturers as users of digital services. Users have access to all important areas with just one login, such as the shop system, app licensing, user administration and the technical connection of the machines. In addition, tapio provides the corresponding framework conditions for data protection and ownership in accordance with the standards of the European General Data Protection Regulation.

In addition, HOMAG INTELLIGENCE forms the solid backbone for seamless networking of furniture production processes. From the concept of the desired furniture through to production, this platform seamlessly connects all data between different software systems, process steps and machines and enables an efficiently organized process — from start to finish.