Ink Big. Digital edge printing is revolutionizing furniture construction.

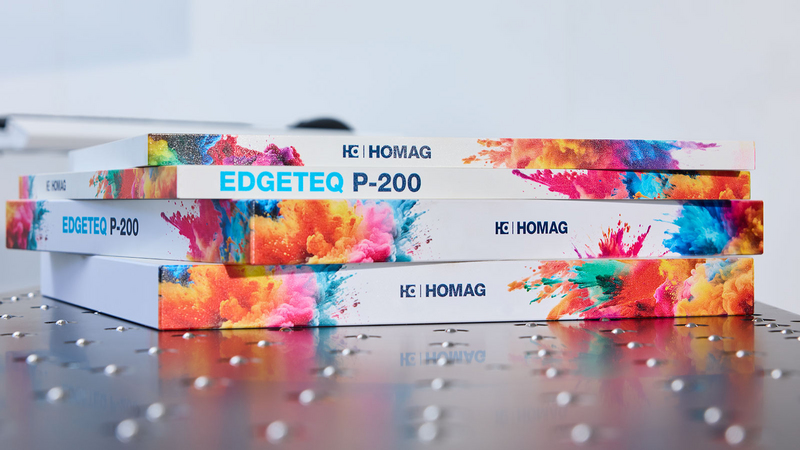

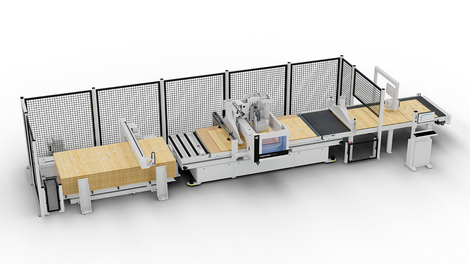

EDGETEQ P-200: Digital edge printing for woodworking shops

The EDGETEQ P-200 offers countless options for creative edge processing. For small and medium-sized companies, the digital printing machine from HOMAG is a real game changer: It prints edges with patterns, designs, images or logos — and all in brilliant four-color printing. The EDGETEQ P-200 therefore opens new doors for carpenters and joiners to raise their game in the market—whether it is furniture construction, interior fittings or trade fair construction—with creative solutions and to specifically respond to customer requirements.

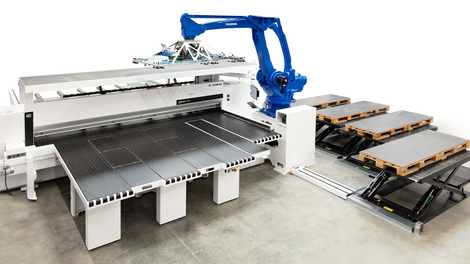

The EDGETEQ P-200 is compact, powerful and combines many practical features, including automatic workpiece cleaning, ink refill system and a fifth color channel for applying a protective coating. This makes it the ideal solution for woodworking shops and manufacturers who produce personalized furniture and individual designs. Creative design ideas can also be implemented quickly and easily in shop fitting and trade fair construction.

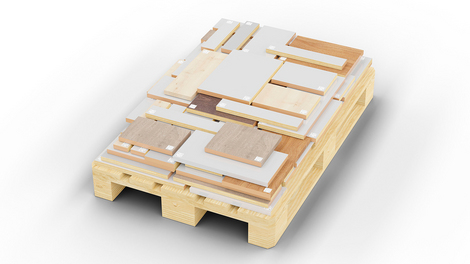

The machine can process components with a length of 120 to 2500 mm, a width of 120 to 700 mm and a thickness of 8 to 38 mm. It is ideal for decorating neutral workpieces or for direct printing on MDF boards.

The EDGETEQ P-200 enables you to visualize your design ideas directly — without the need for complex sample fronts. This saves time and costs and makes coordination with the customer much easier. Thanks to a user-friendly print control unit via the woodCommander interface, the machine is easy to operate and works fully automatically right to the end.