Interview about the HOMAG INTELLIGENCE digital platform

With BM magazine and HOMAG software experts Hendrik Albers and Alexander Lindner

BM magazine, 10/2025 edition. Read the interview on BM Online.

HOMAG INTELLIGENCE is the first solution on the market that ensures a seamless data flow from furniture sales to production, heralding a new era of consistently and continuously networked workshops. In an interview with BM magazine, software experts Hendrik Albers and Alexander Lindner explain what HOMAG INTELLIGENCE is all about and what opportunities the digital platform offers, especially for carpenters and joiners.

BM: HOMAG INTELLIGENCE was demonstrated for the first time at LIGNA 2025 in Hanover. What exactly is it all about?

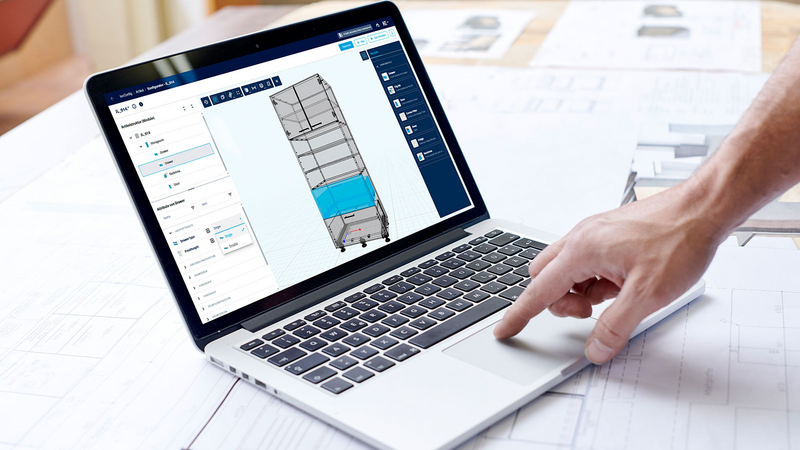

Hendrik Albers: HOMAG INTELLIGENCE is a new digital platform for the sale, configuration and production of furniture and interior fittings. As the first modular solution on the market, it ensures end-to-end networking of all work steps. The open, cloud-based platform seamlessly connects all data — regardless of the machine pool, software you already use or the size of the company.

BM: Can HOMAG INTELLIGENCE be described as a digital optimization toolkit?

Hendrik Albers: It's more like a digital solution toolkit that can be used by carpenters and joiners, but also by larger companies, to optimize their data and processes. Depending on the requirements, this means a company can either choose the complete, end-to-end solution or selected individual apps that can be used on their own or purchased as a bundle in defined packages. This is comparable to Microsoft: With Microsoft 365, the company offers an end-to-end platform with various products and bundles these into packages. There are also tools and services to suit all company sizes.

BM: Who is the target audience?

Alexander Lindner: The target audience is currently all operators in the furniture production sector whose products consist mainly of panel materials. The production spectrum ranges from home furniture and kitchens to cut-to-size parts and individual shop fitting and interior fitting projects. Every business can benefit from individually customizable platform modules.

BM: How does the size of the company affect this?

Alexander Lindner: HOMAG INTELLIGENCE can be used to meet the individual requirements of businesses ranging from small carpenters to the furniture industry. The platform modules enable small, medium and large businesses to offer tailor-made solutions. There are therefore no restrictions on the number of employees required.

BM: HOMAG promises that, for the first time, it is now possible to link all data from sales to the production of the furniture. Can you give specific examples?

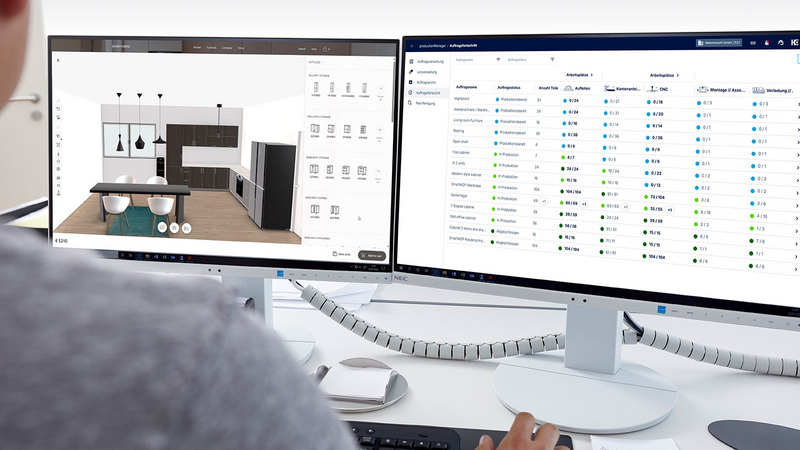

Hendrik Albers: Let's take a look at a carpenter who offers custom kitchens. Using our design libraries, the business is able to create images of their entire product catalog. The products are then not only immediately available in the planning software during sales talks, but all production data and information such as parts lists, CNC programs or the work surface are also created automatically in the background at the same time.

In concrete terms, this means that furniture planned by the sales department does not have to be laboriously drawn, constructed and tested again in work preparation. A major highlight is that customer requirements can also be taken into account or subsequently adapted at any time and with almost no significant effort. In short, all the data is always up to date in every location. No duplicate data management, no complex data handling, fewer errors. In this way, we make carpenters faster and more efficient.

Alexander Lindner: The same materials master database can also be used everywhere from furniture sales to the saw or nesting CNC. Where material data was previously maintained in several locations or stocks had to be laboriously checked, all the information is now in one place. In addition, we also integrate partners into this platform and the systems of these partners also have direct access to the master data in the platform.

BM: What makes HOMAG INTELLIGENCE unique and what specific benefits does it offer?

Alexander Lindner: HOMAG INTELLIGENCE is currently the only completely cloud-based platform in the industry that offers a seamless process from sales to production with no internal interfaces and with central data storage. We are completely open and modular. This allows us to connect carpenters and joiners, service providers, manufacturers, customers, materials and software suppliers.

BM: Can you explain the term platform in more detail? Is this a mixture of software and service components?

Hendrik Albers: HOMAG INTELLIGENCE is the foundation for seamlessly networking all work steps. With it, we provide app and software solutions. In addition, our experts assist you with the selection and implementation of the right modules.

If we take cutting optimization in small businesses, for example: This is usually done by the carpenters themselves. HOMAG INTELLIGENCE strives to enable carpenters and joiners to easily get started with using the individual apps themselves. Examples of this include the cutting assistant, cutting optimization or edge management, as well as the edgeband assistant. When it comes to larger, complex solutions, we offer assistance when making the selection and during setup.

BM: Which problems and capacity bottlenecks typically faced by the carpentry and joinery trade can HOMAG INTELLIGENCE solve?

Alexander Lindner: Let's take hardware as an example. This is usually comes down to significant investments in servers and operating systems. Since HOMAG INTELLIGENCE is completely cloud-based, there is no need to procure hardware or set up a network structure. In addition, HOMAG INTELLIGENCE has completely done away with internal interfaces and the large effort usually associated with them.

Data management is another example. We use a centralized material master for panels, edges, fixtures and textures. In practice, different systems such as ERP or CAD, which are maintained individually, are often in use. This is time-consuming and prone to errors. Here, we help carpenters to save capacity by organizing these materials centrally while still allowing the user to access existing master data from our software partners.

BM: Can carpenters and joiners start small, with little investment and then grow with together with their needs?

Alexander Lindner: Costs associated with the hardware and network structure are largely eliminated. This means that you can try out software at any time at no risk and without having to invest large amounts of money in hardware. Furthermore, carpenters can start with individual modules of the platform — just like with our existing and proven digital products. Over time, this solution can grow gradually. We also help companies launch new business models quickly. This could be a new distribution channel using a configuration solution, for example. Here, we provide support, among other things, with predetermined libraries and design principles.

BM: A configurator like this would then be a supplement to the CAD system in use. How do I combine the data from both systems for production?

Alexander Lindner: This depends on the operational structure. A smaller company with a CAD/CAM system can use solutions from our platform to significantly optimize its existing process, for example in the area of material management or production organization. If users use their own CAD system and our configurator, the standardized interfaces enable all the data to be sent to production via the same channel. The data from both applications can be transferred to production together. Cutting optimization is one example of this.

BM: What are the technological requirements of HOMAG INTELLIGENCE?

Hendrik Albers: It is always used in your browser — regardless of whether that is Google Chrome, Microsoft Edge or Apple Safari. Some apps can also be installed, be it on a tablet or a computer or laptop. In this case, commercially available hardware is sufficient and it can be used regardless of the operating system. Central data storage is always carried out in the cloud. This is how we use HOMAG INTELLIGENCE to prepare businesses for the future.

BM: You said that HOMAG INTELLIGENCE is designed in a similar way to the Microsoft environment. There, software is no longer purchased, but rather licensed. How does this work for HOMAG INTELLIGENCE — does the user buy the software and modules or can they use them as required according to the "Software as a Service" principle?

Hendrik Albers: Our customers from the carpentry and joinery trade are fortunately now very open to "Software as a Service" and also to the cloud. Basically, this depends on the way the solution is put together. Web-based applications use the "Software as a Service" model and are used as required. Software solutions such as SmartWOP will continue to be based on a one-time payment.

BM: Many woodworking shops use a CAD system in combination with ERP software. How can HOMAG INTELLIGENCE optimize processes in such a typical woodworking shop?

Alexander Lindner: Our core approach is to integrate existing CAD and ERP systems into the platform. We have already implemented this with a large number of partners via standardized interfaces. The joiner can then connect their CAD system to HOMAG INTELLIGENCE almost as easily as plug and play. In principle, the user then has access to all modules that they want to use after CAD. Among other things, they can access the material data or use optimization solutions directly on our platform. Or they can provide information for employees who are accessing it from the CAD system. This information can be easily distributed to employees via our cloud. In this way, we enable transparent and needs-based communication in a very concrete manner. This is also centralized and coordinated: Every employee receives exactly the information they need at all times.

BM: Is the ultimate performance of HOMAG INTELLIGENCE dependent on whether I use HOMAG machines?

Alexander Lindner: The situation here is similar to that of Microsoft: To a certain extent, the tools work a little better on Microsoft hardware in some cases. The same applies to the Homag software solutions. The special connectivity features for Homag machines offer a particularly wide range of options. At a basic level, however, HOMAG INTELLIGENCE is completely open and flexible when it comes to communication with machines and technologies from other manufacturers, and also works with these systems without any problems.

The interview was conducted by BM Editor-in-Chief Christian Närdemann.

You can read more about how the carpentry and joinery trade can benefit from the new HOMAG INTELLIGENCE platform in another article from BM magazine 10/2025.