A reception desk that makes a design statement, plus 680 identical nightstands. Custom-made products, delivered on schedule and with no compromises on quality: business as usual for Felix Graf GmbH. Based in the Bavarian Forest, this complete interior furnishing company combines traditional woodworking with modern machine technology, creating truly impressive spaces.

A third-generation family business.

It all began 70 years ago in 1955, in Zenting, Lower Bavaria, when Felix Graf senior founded a traditional carpentry and furniture-making business. When he was taken ill, he was joined in the business by his son, Felix Graf junior, who was at that time completing his studies in interior design. Two days at college, three days at work – it was a challenging time, but sharing the work paid dividends. He brought new ideas and a new direction to the business. From the late 1970s onwards, the company increasingly moved toward interior fittings, with a focus on store fittings. Today, Felix Graf GmbH is a valued partner throughout Europe for complete solutions in the area of interior furnishings for real estate and hotels.

From studwork to sockets.

Graf customers are buying a lot more than just furniture. "It isn't just a joinery service," explains Valentin Graf. "We deliver complete rooms." Brothers Valentin and Felix Constantin Graf now run the company together with their parents. They will officially join the management board later this year. So management. Staff turnover is low and loyalty high: The people who work at Graf stick around – often for decades. And with good reason: "We invest in people, not just in machinery," explains Felix Constantin Graf.

The company takes on at least two apprentices each year; it offers development opportunities and, above all, responsibility. Employees who have 30 or 40 years of service run their areas of the business as if they were their own. Technology – in production and beyond. The company has relied on HOMAG technology since the 1990s and

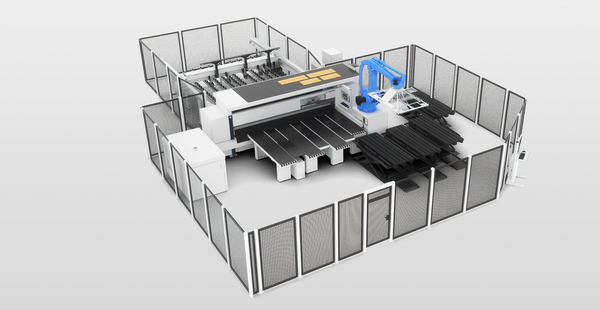

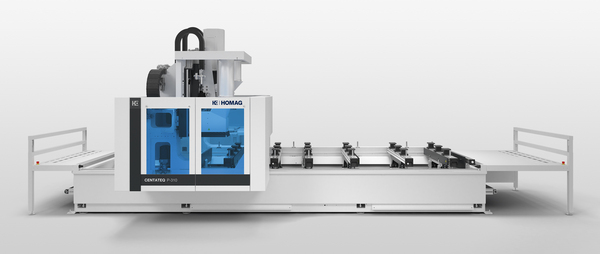

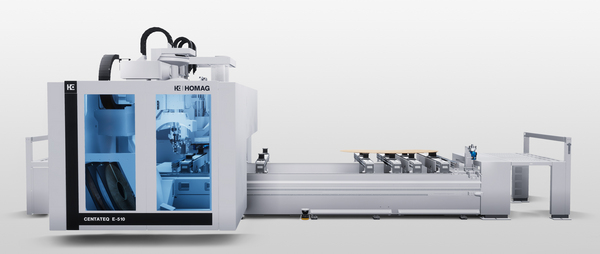

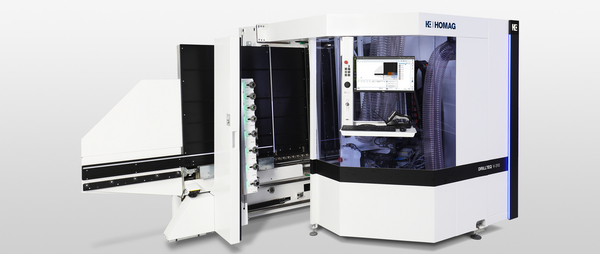

currently has eight HOMAG machines in the workshop: three processing centers, an edge banding machine with automatic return, a panel dividing saw with storage, a case clamp, plus a 5-axis CNC that will be coming soon. "Our HOMAG machines are extremely reliable and easy to operate," explains a very satisfied Valentin Graf. What the technology does is impressive: series production and batch size 1 in a single order? No problem. "As an example, we are constructing 680 identical nightstands, and as part of the same project a single stylish reception desk. Thanks to HOMAG, we can do both. On time, with precision and to the highest quality standards."

The milestones keep coming.

The company now has some 70 employees, around 40 of whom work in production; the rest work in order processing, administration and project management. Staff turnover is low and loyalty high: The people who work at Graf stick around – often for decades. And with good reason: "We invest in people, not just in machinery," explains Felix Constantin Graf. The company takes on at least two apprentices each year; it offers development opportunities and, above all, responsibility. Employees who have 30 or 40 years of service run their areas of the business as if they were their own.

Technology – in production and beyond.

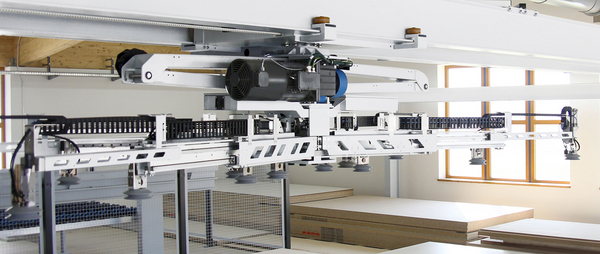

The company has relied on HOMAG technology since the 1990s and currently has eight HOMAG machines in the workshop: three processing centers, an edge banding machine with automatic return, a panel dividing saw with storage, a case clamp, plus a 5-axis CNC that will be coming soon. "Our HOMAG machines are extremely reliable and easy to operate," explains a very satisfied Valentin Graf. What the technology does is impressive: series production and batch size 1 in a single order? No problem. "As an example, we are constructing 680 identical nightstands, and as part of the same project a single stylish reception desk. Thanks to HOMAG, we can do both. On time, with precision and to the highest quality standards."

The company's high standards are also reflected when it comes to energy usage – wood waste is used to generate heat, making it possible to heat the entire joinery without the need for fossil fuels. Excess heat is even fed into the local district heating grid. In addition, on average 40% of the company's electricity needs are covered by a photovoltaic system. When the sun shines, not only do the PV modules charge up, but there is also a gentle hum around the building because the family has a cousin who is a beekeeper and the honey he makes on company premises is regularly offered to customers to welcome them.

The next generation is stepping up.

Felix Constantin and Valentin Graf are not simply managing directors in waiting. They have been actively involved in shaping the direction of the company for some five years now. With a master's degree in interior design from the renowned Royal College of Art in London and practical experience acquired in Milan, the older of the two brothers brings fresh ideas to the company. And with his dual studies in interior design and a master's degree in wood technology, Valentin has valuable specialist knowledge to contribute. "Our goal is clear," says Felix Constantin Graf. "We want to firmly establish the Graf name as a quality brand in the interior furnishings space." They also have a vision for the site itself: A large new building was added in 2014, with another production hall following just this year – the next step is to expand the office space.

There is one key reason why the two worlds–design and technology–intertwine so naturally at Graf: The builders and interior designers feel understood. Because the company speaks their language. The team impresses with its flexibility, precision and feel for the fine details. The result is rooms that become living spaces, if only for a short time.

Article published in the customer magazine Maßarbeit, Issue 14/2025

“As an example, we are constructing 680 identical nightstands, and as part of the same project a single stylish reception desk. Thanks to HOMAG, we can do both. On time, with precision and to the highest quality standards.”Valentin Graf, wood technician and soon-to-be board member

Felix Graf GmbH

Products: Complete interior furnishings

Location: Zenting, Germany

Founded: 1955

Employees: 70

First HOMAG machine: 1997

HOMAG machine pool:

- MPH400 case clamp (comparable to today's CABTEQ S-200)

- Venture 22XL CNC processing center (comparable to today's CENTATEQ E-310)

- BMG 511 CNC processing center (comparable to today's CENTATEQ P-510)

- DRILLTEQ V-310 CNC processing center

- EDGETEQ S-500 edge banding machine with LOOPTEQ O-400 automatic return

- SAWTEQ S-300 panel dividing saw with STORETEQ P-300 automatic panel storage