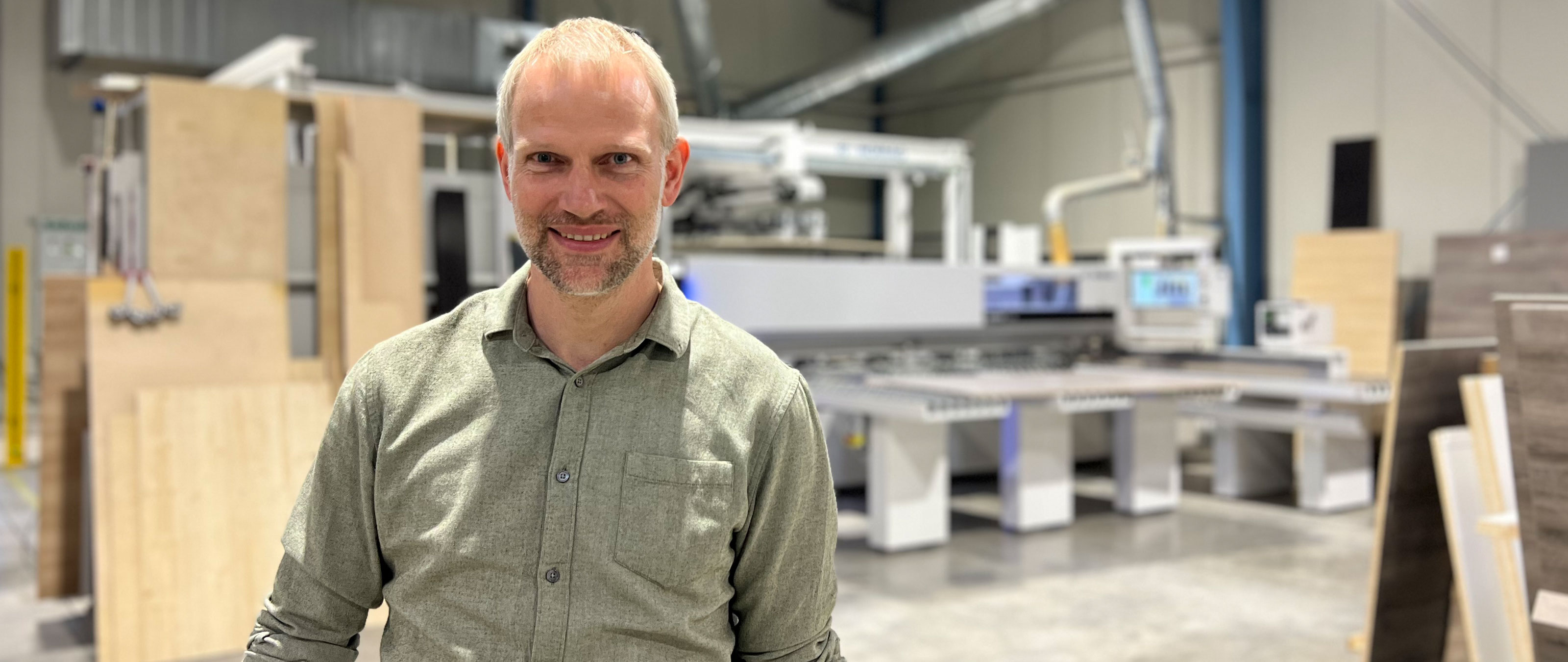

In his joinery, Rainer Volkery has charted the course for the future. With the move to a new hall and the additional available space associated with it, he has entered a new technological phase. His first step has involved restructuring the panel cutting process. Technology partner HOMAG has supplied the space-saving combination of panel dividing saw and single-axis feeder.

It all started in 2006: Rainer Volkery, then a newly qualified master carpenter and operations manager, sets up his own business in his parents' garage in Ostbevern near Münster. Following a swift relocation to a larger hall, his team grew by two journeymen and his machine pool comprised both standard machines as well as an edge banding machine and a CNC processing center.

This spring, he'll take the next step: His team, which has now grown to 15 employees (including four trainees at present), will move to a new hall and will have three times as much space as before, totaling around 1000 m². "We have now entered a new era," says the master carpenter, adding: "Now we are preparing for the future, step by step."

Sustainability is more than just a word

The joinery mainly processes panel material. But solid wood and veneer also play an vital role. Rainer Volkery attaches great value to sustainability. In this regard, he has no interest in hollow words. He wants to know where his material and supplies come from and actively brings this into question in specific cases. The master carpenter also selects suppliers based on this mindset. Those who fail to perform in a transparent and verifiable manner will struggle to win over Rainer Volkery.

He relies on solid wood from regional sources. The joinery almost exclusively processes domestic wood, which the company also dries and cuts in-house. Volkery: "I can always give my customers an authentic story about the tree from which their furniture was made. This leaves a good impression."

Exhibition shows a wide range of skills

In a small but very elegant exhibition, which still continues to be stocked and completed, the joinery presents insights into its wide range of products: kitchens that contain high-quality devices, solid wood furniture, sophisticated lighting technology and much more. This demonstrates at a glance a distinctive set of design skills. The joinery is also a retailer of Raumplus and Miele products.

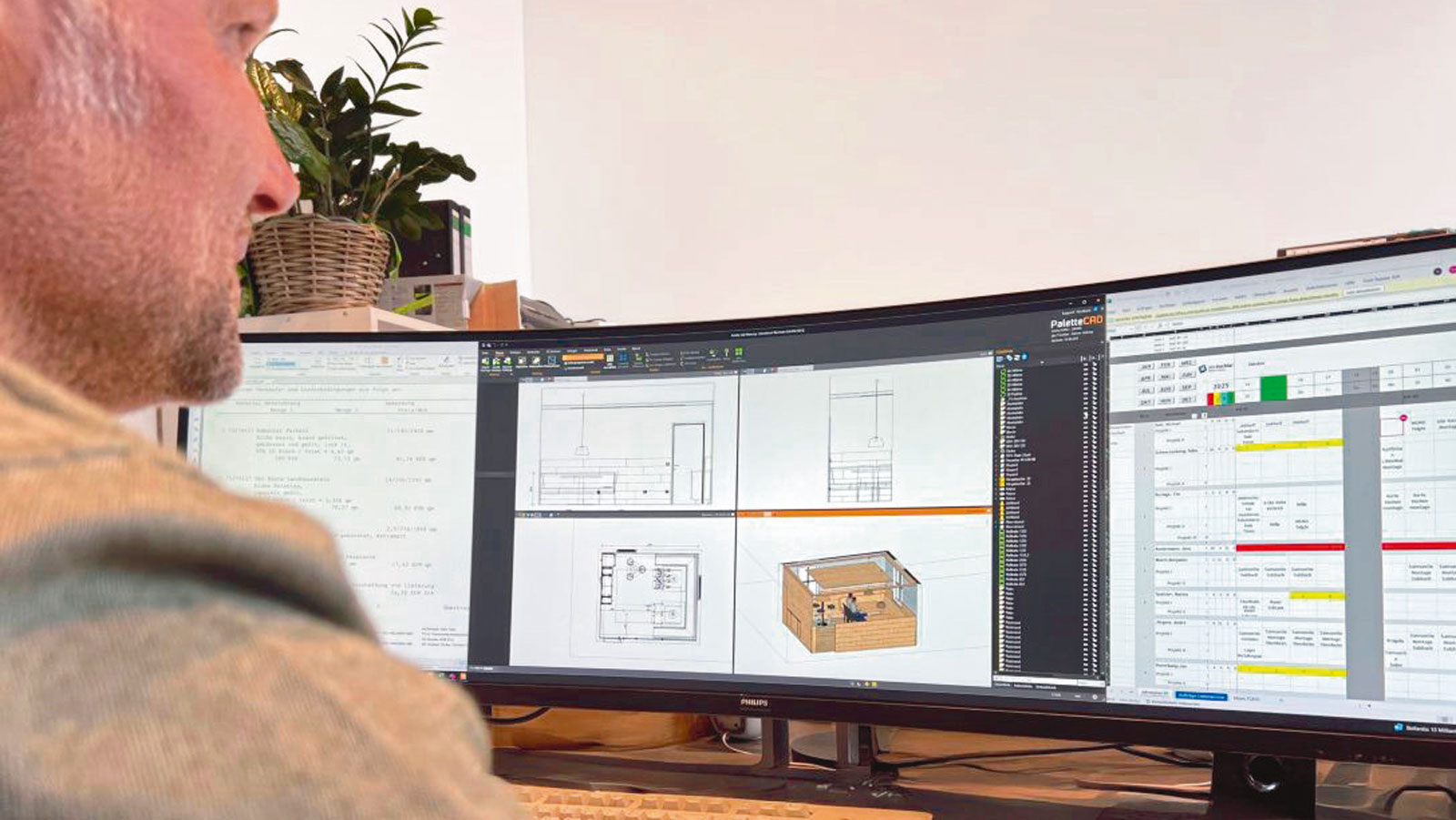

Rainer Volkery relies on flat hierarchies within his company. Everyone is on an equal footing here, and if an extra pair of hands is needed, the boss can also operate all of the machines himself. The master carpenter's primary focus is on customer acquisition and the design and planning of individual furniture pieces and interior fittings. Two experienced colleagues are available to assist him in the work preparation. In terms of software, PaletteCAD and the industry software Pincalc are used.

Once planning is finished, work preparation hands over the respective project folder including the parts list to a journeyman. They are then entirely responsible for the order — from programming the CNC data at specially installed workstations, through coordination during production, right through to assembly at the customer's site.

Networks and strengthening the woodworking sector

Rainer Volkery is a dedicated networker. In this regard, keeping an eye on the woodworking sector and its points of interest is crucial to him. In his opinion, "we need to strengthen the woodworking sector, not push the industry." By this, he means that fellow joineries should network with and support each other rather than ordering from industrial suppliers, which ultimately harms the woodworking sector and weakens it in the long term. He places great importance on ensuring that as much added value as possible remains within the woodworking sector. For example, he cooperates with a bathroom planner and sanitary experts to offer sophisticated solutions from a single source to end customers.

Another approach involves cooperation with fellow joineries. Thanks to technological options, which have recently been significantly expanded, the company is able to support panel processing — from cutting, through edge banding, and all the way through CNC processing. Conversely, he also likes to fall back on the expertise of fellow joineries in areas outside of his joinery's core portfolio.

Productivity quadrupled: Panel cutting at the next level

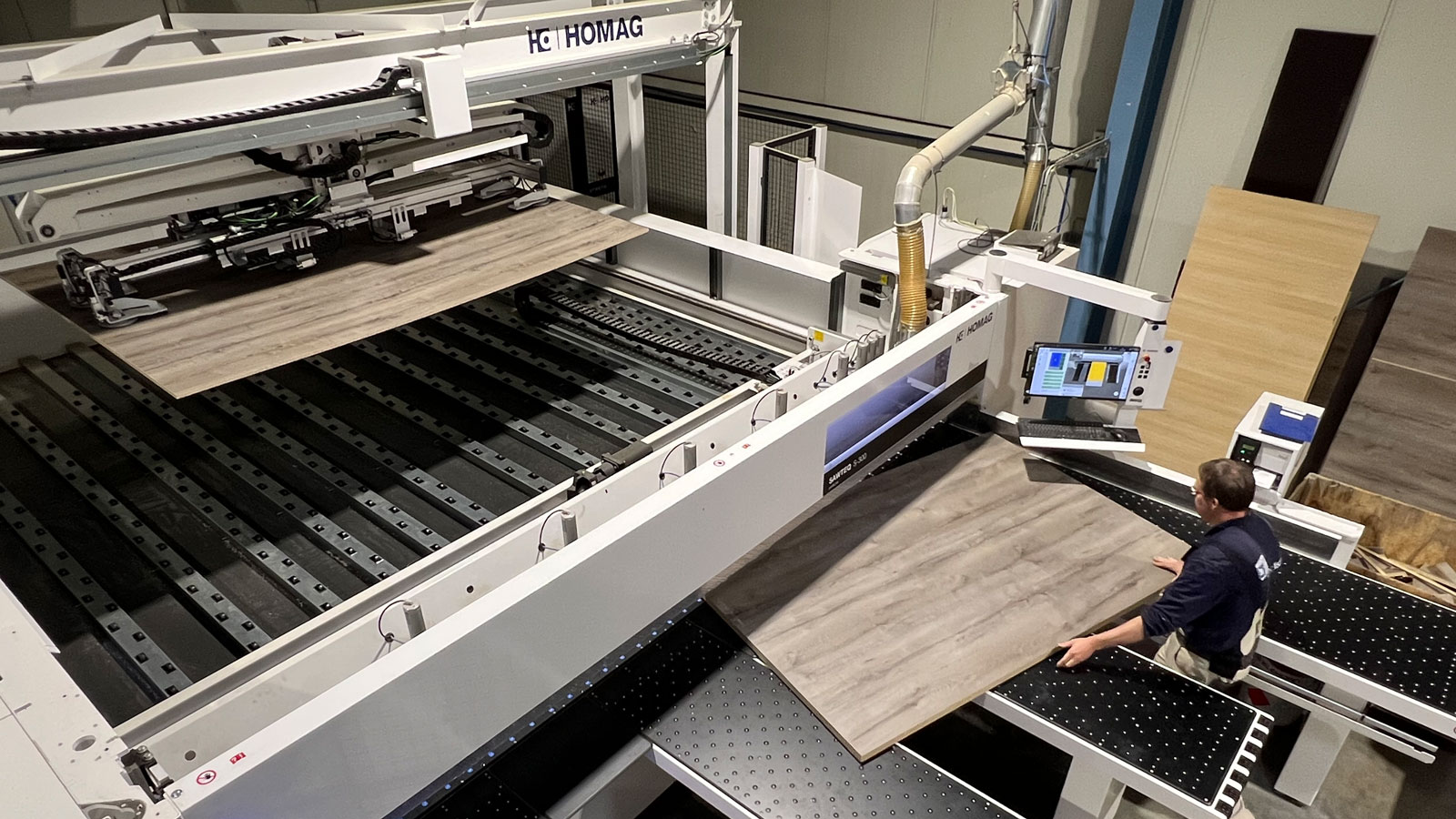

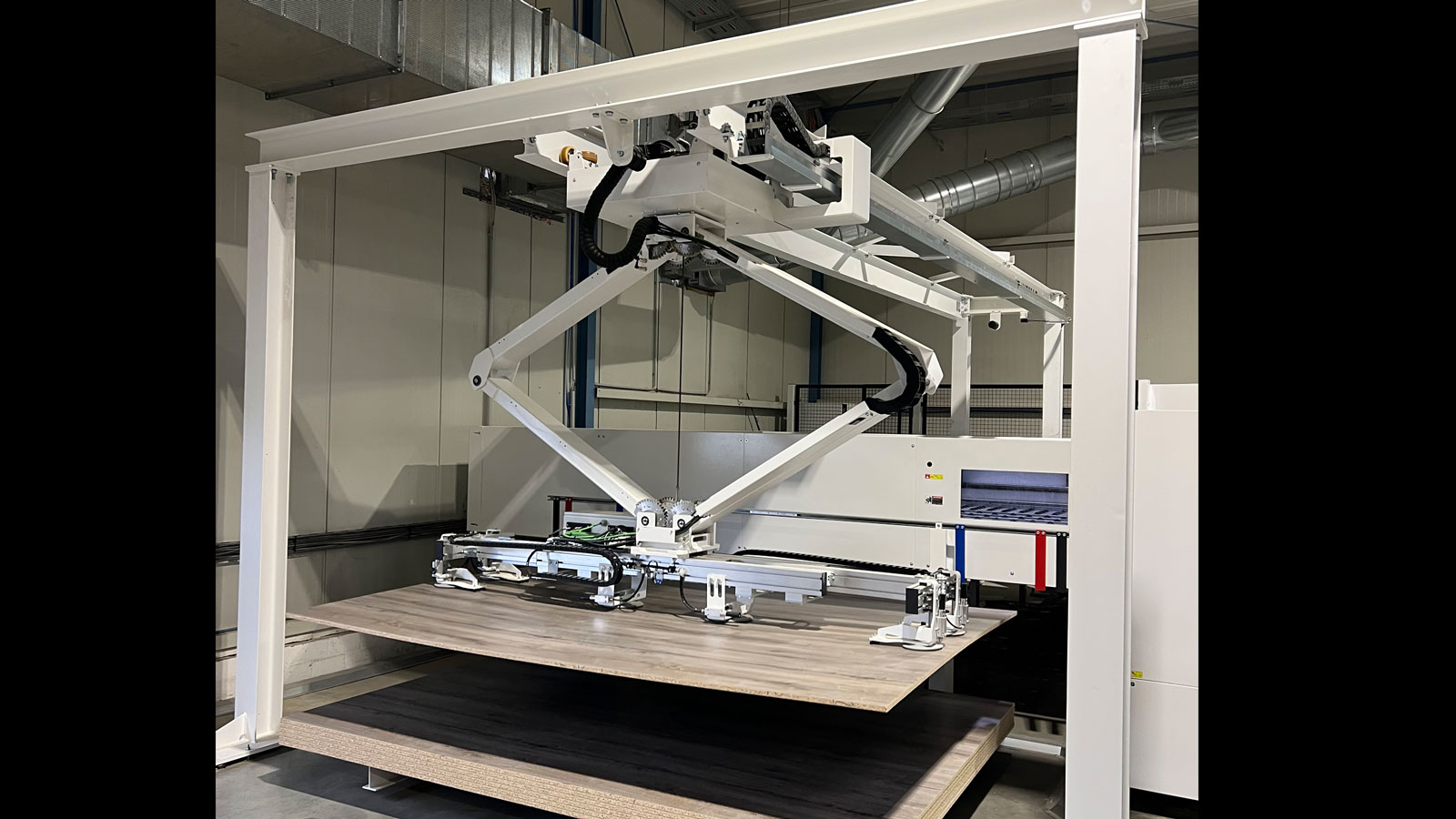

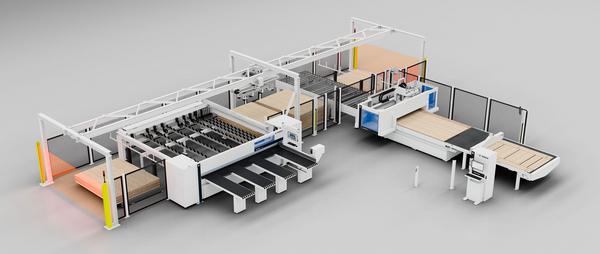

With the move to the new hall and the additional available space associated with it, Rainer Volkery decided to invest in new panel dividing technology. The classic vertical saw has been replaced by the bespoke combination of a SAWTEQ S-300 panel dividing saw (cutting length 4300 mm) and a new STORETEQ F-100 single-axis feeder from HOMAG. This combination requires very little additional space next to the panel dividing saw. There, the panels to be divided are supplied. The panels are then fed into the saw fully automatically using a vacuum suction unit. This is done in parallel with the cutting process on the saw and enables work to be performed without interruption.

Ultimately, the joinery quadrupled its capacity for panel cutting through this investment. The workflow is also much smarter and less demanding for the machine operator. Rainer Volkery, who outs himself as a HOMAG fan during our conversation, is very pleased with the performance.

An sophisticated, end-to-end workflow

If a piece of furniture or equipment is planned in PalletCAD, the parts list is transferred to Cut Rite, which then makes the finished cutting pattern available for processing on the saw control system.

The STORETEQ F-100 single-axis feeder is also controlled via the CADmatic saw control system. With this setup, the user simply presses the start button — without needing to worry about programming. Meanwhile, Rainer Volkery receives the panels from his supplier in a defined stack — in accordance with the processing sequence, so they simply need to be placed at the side of the saw for the cutting process can begin. The intelliGuide Classic operator assistance system then ensures efficient working: A colored LED strip on the cutting line guides the operator safely and intuitively through the entire cutting process. I think that's great and really smart. Thumbs up!

We look forward to seeing what the next optimization steps will be for Rainer Volkery and his team. I'm cautiously betting on edge processing with return — all made in Schopfloch. Of course, we'll keep our finger on the pulse.

An article by BM trade magazine, 12/25 | Picture and text credits: BM editor-in-chief Christian Närdemann www.bm-online.de