Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

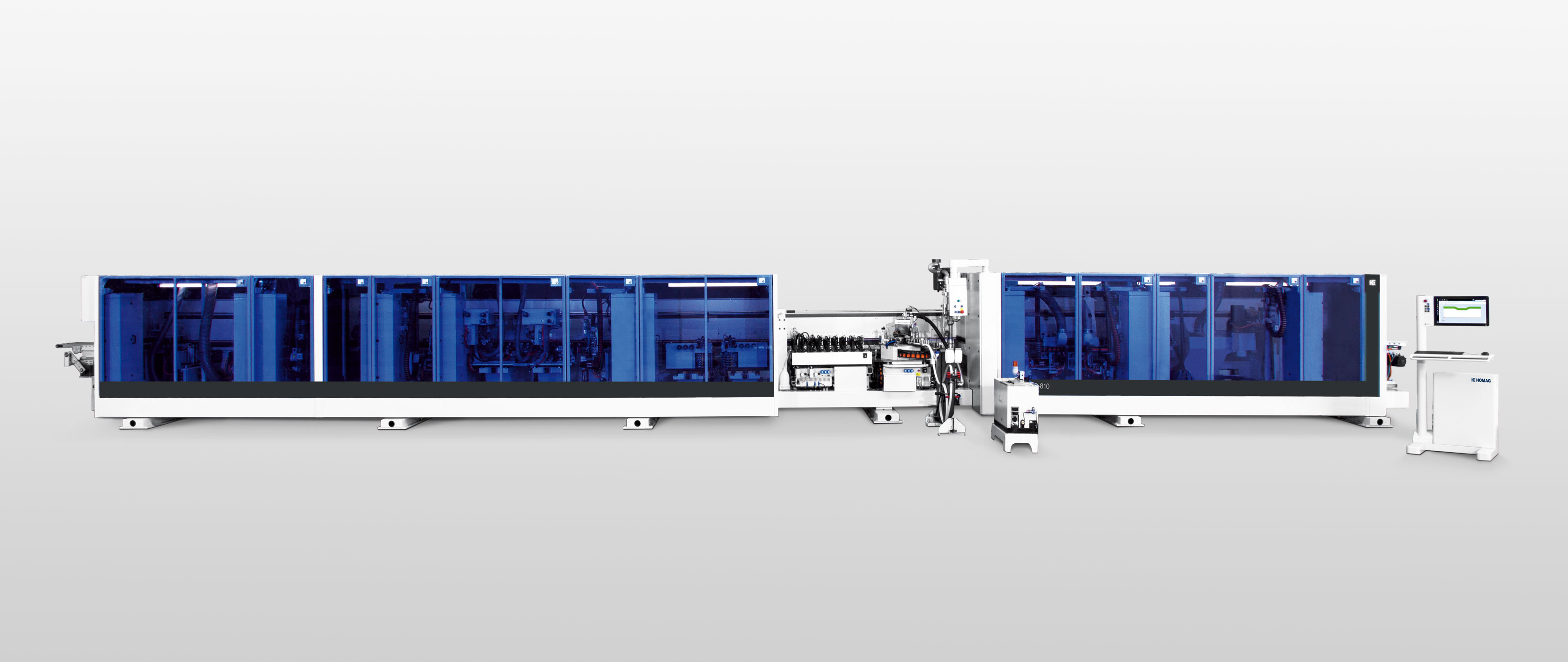

Edge Banding Machines EDGETEQ S-810/CF

Edge Banding Machines EDGETEQ S-810/CF

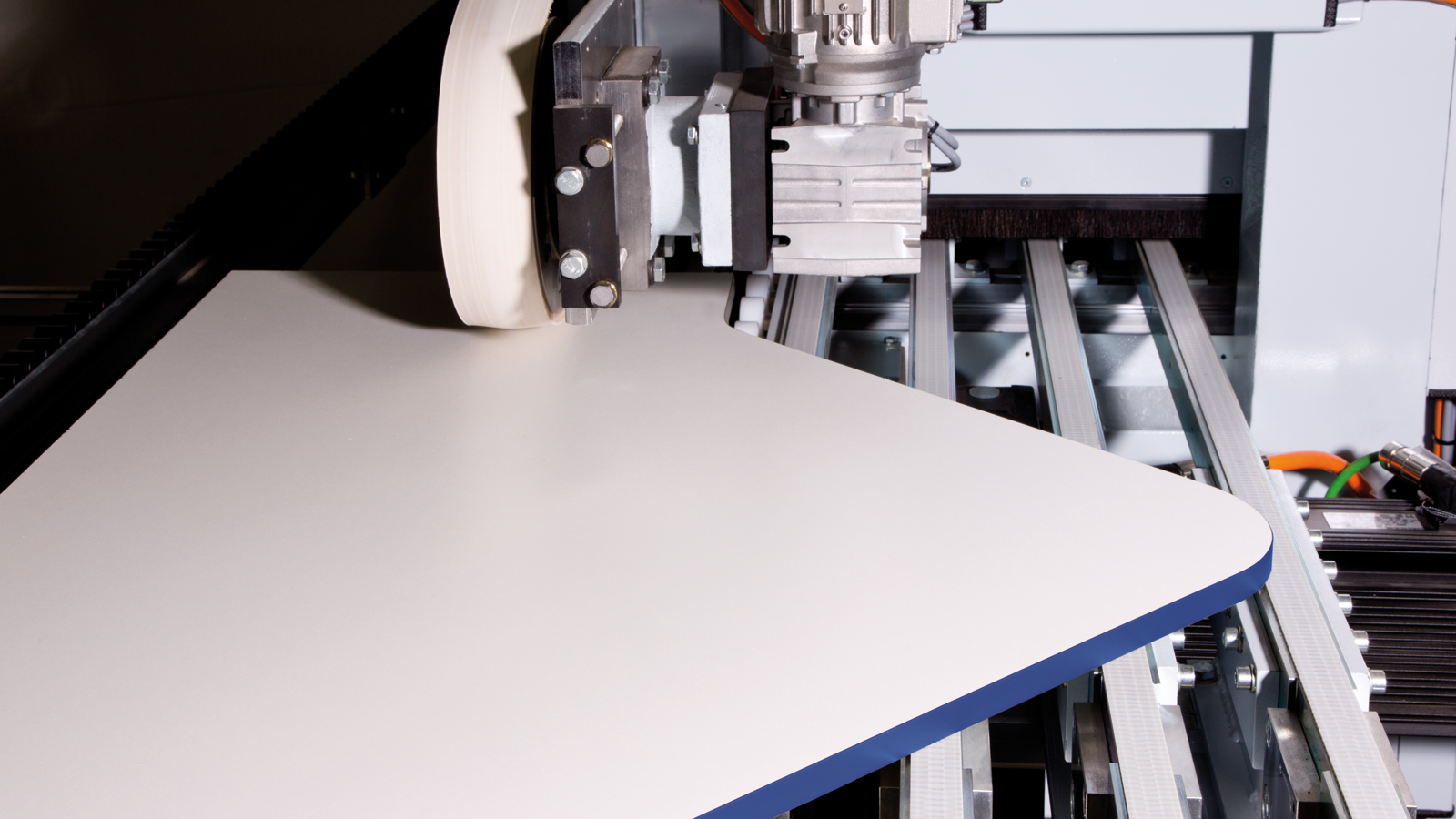

Complete processing of shaped parts in a single run

Rectangular workpieces are quickly turned into attractive contoured furniture parts in a throughfeed process without the need for manual post-processing. The EDGETEQ S-810/CF impresses with exceptional productivity, rapid gluing and precise processing, and with short setup times, our shaped part throughfeed machines are a profitable choice even for small series production. As batch sizes increase, cost efficiency compared to processing centers also improves.

Images

Features

-

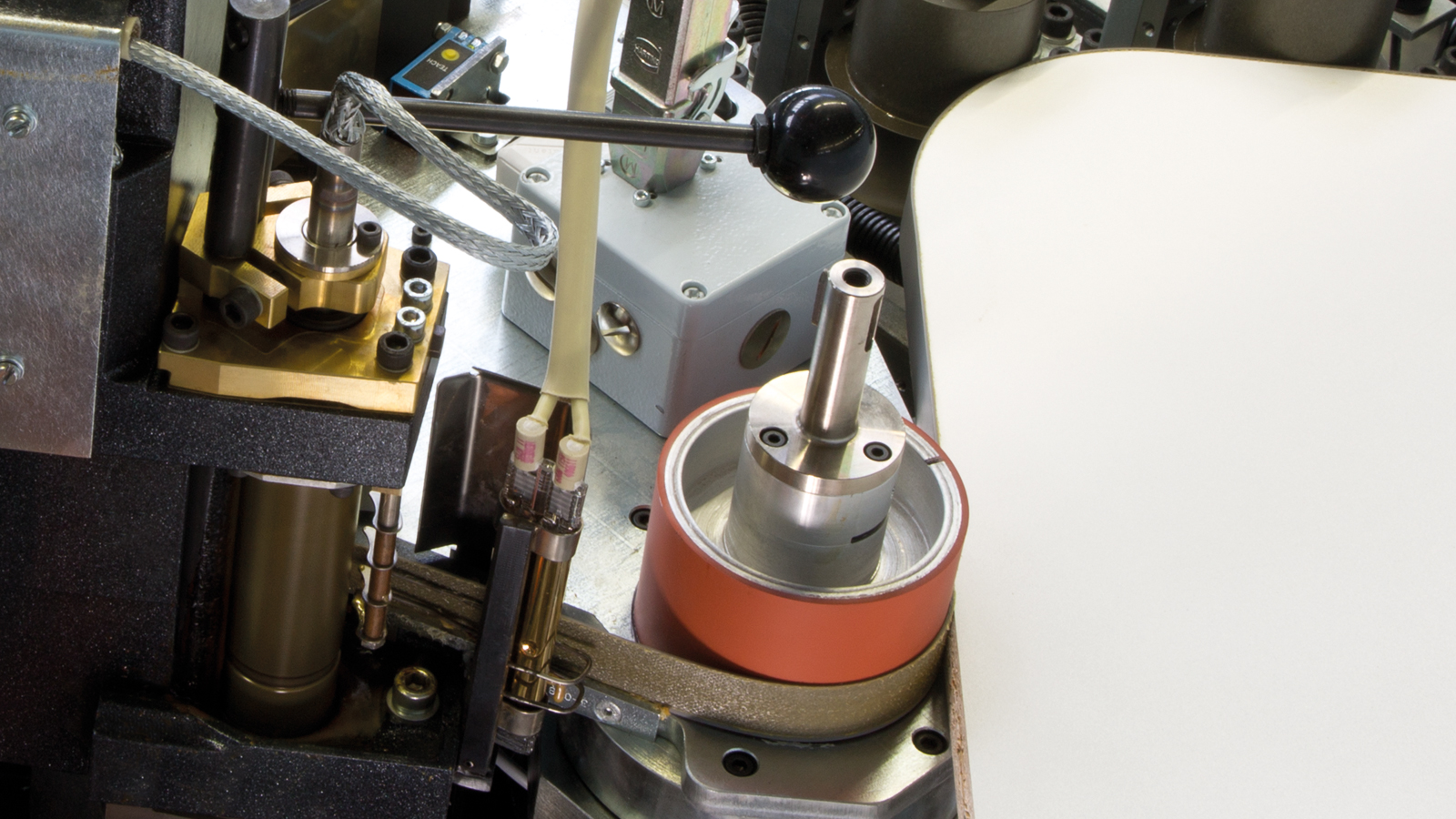

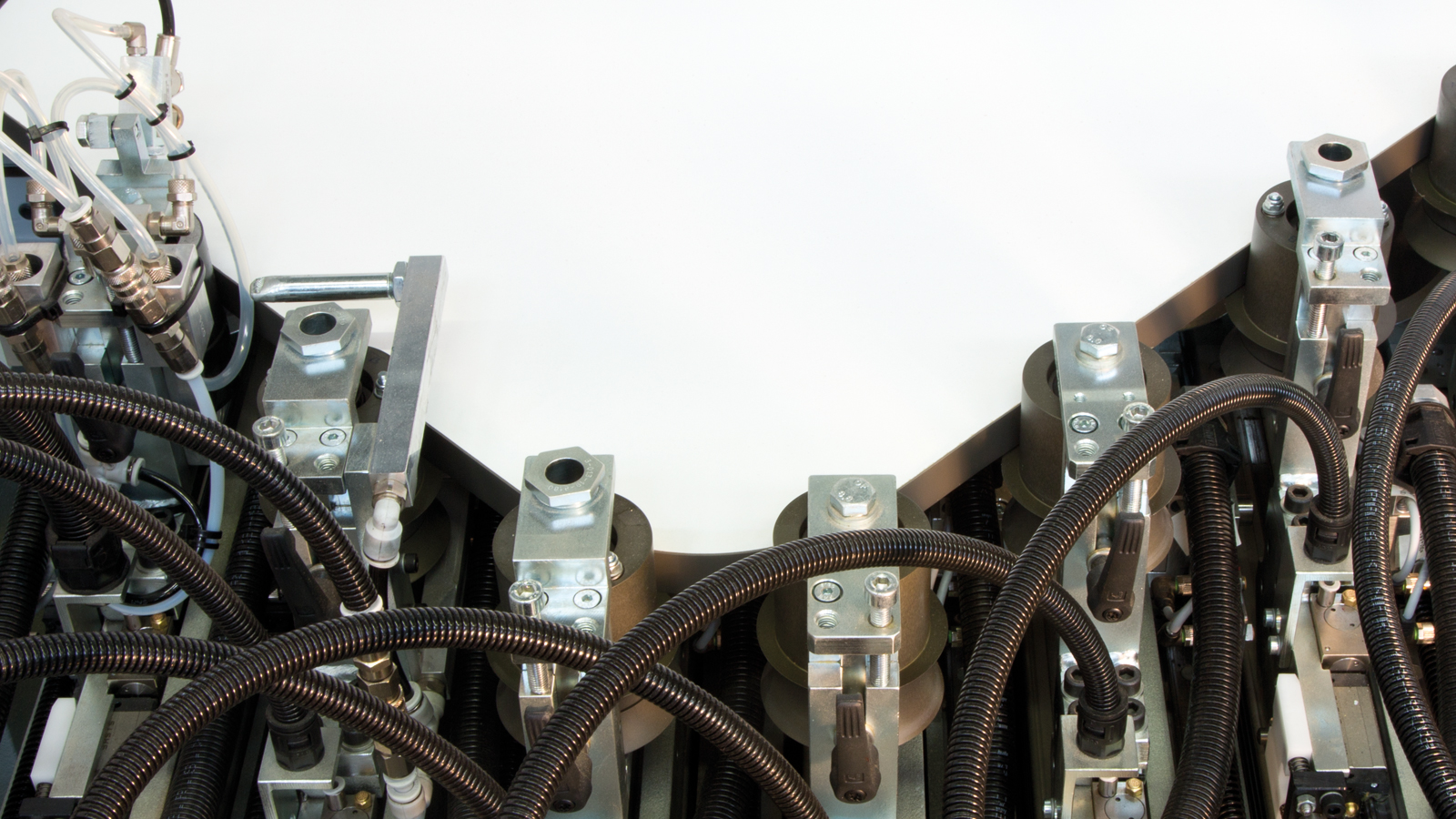

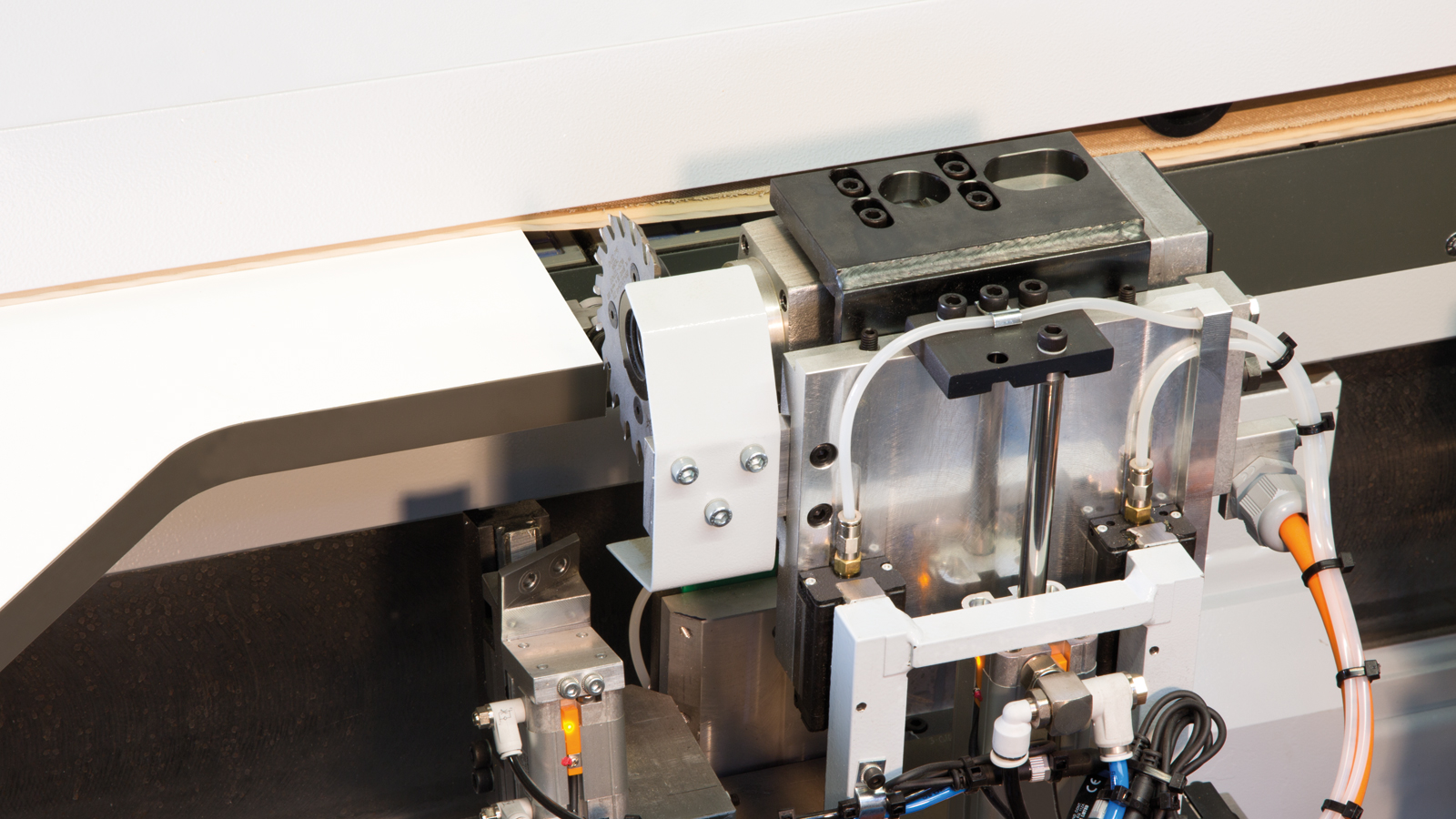

Precise linear drive for the transport chain—with a feed speed of up to 30 m/min—for an exceptionally clean trimming pattern

-

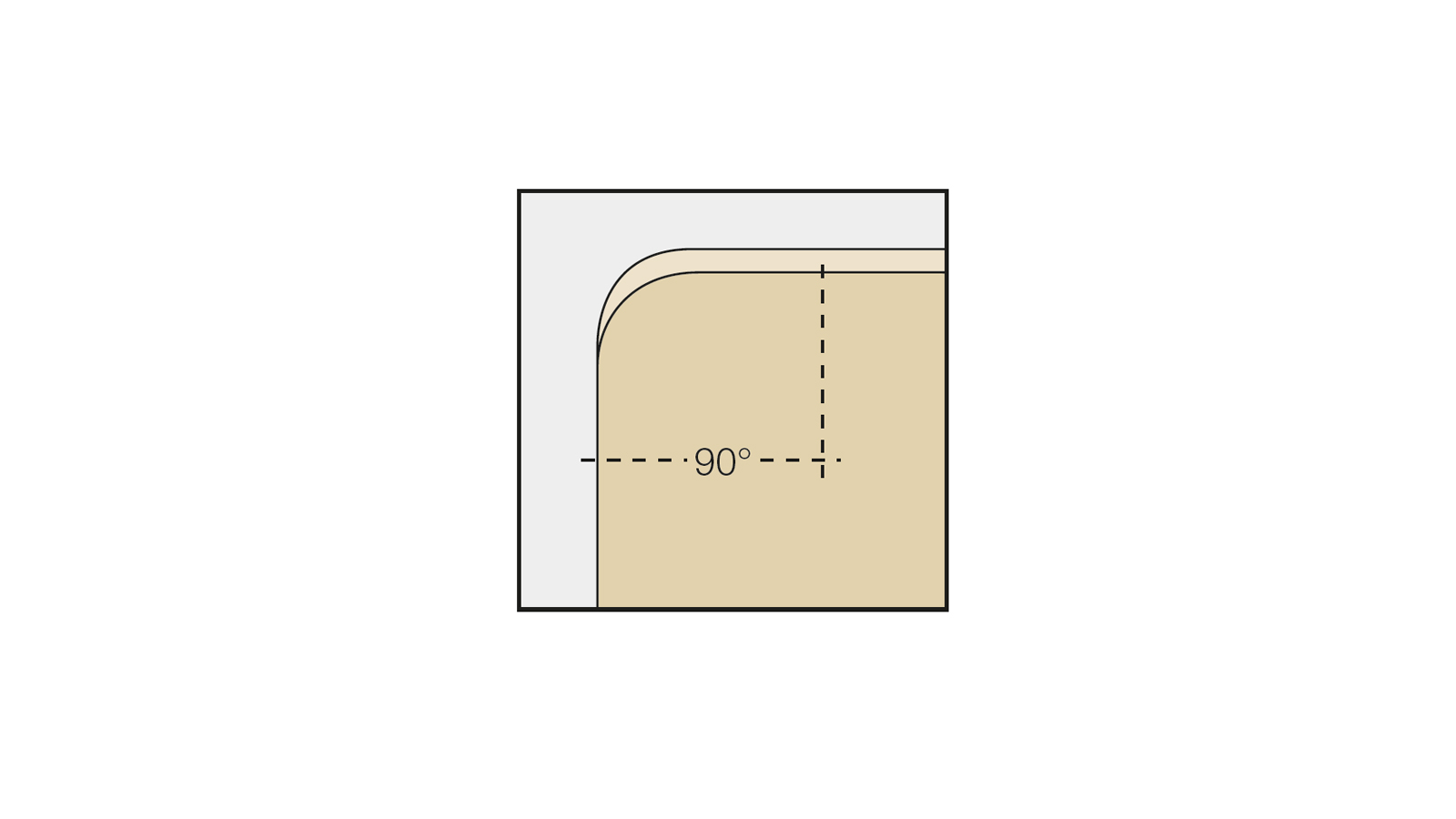

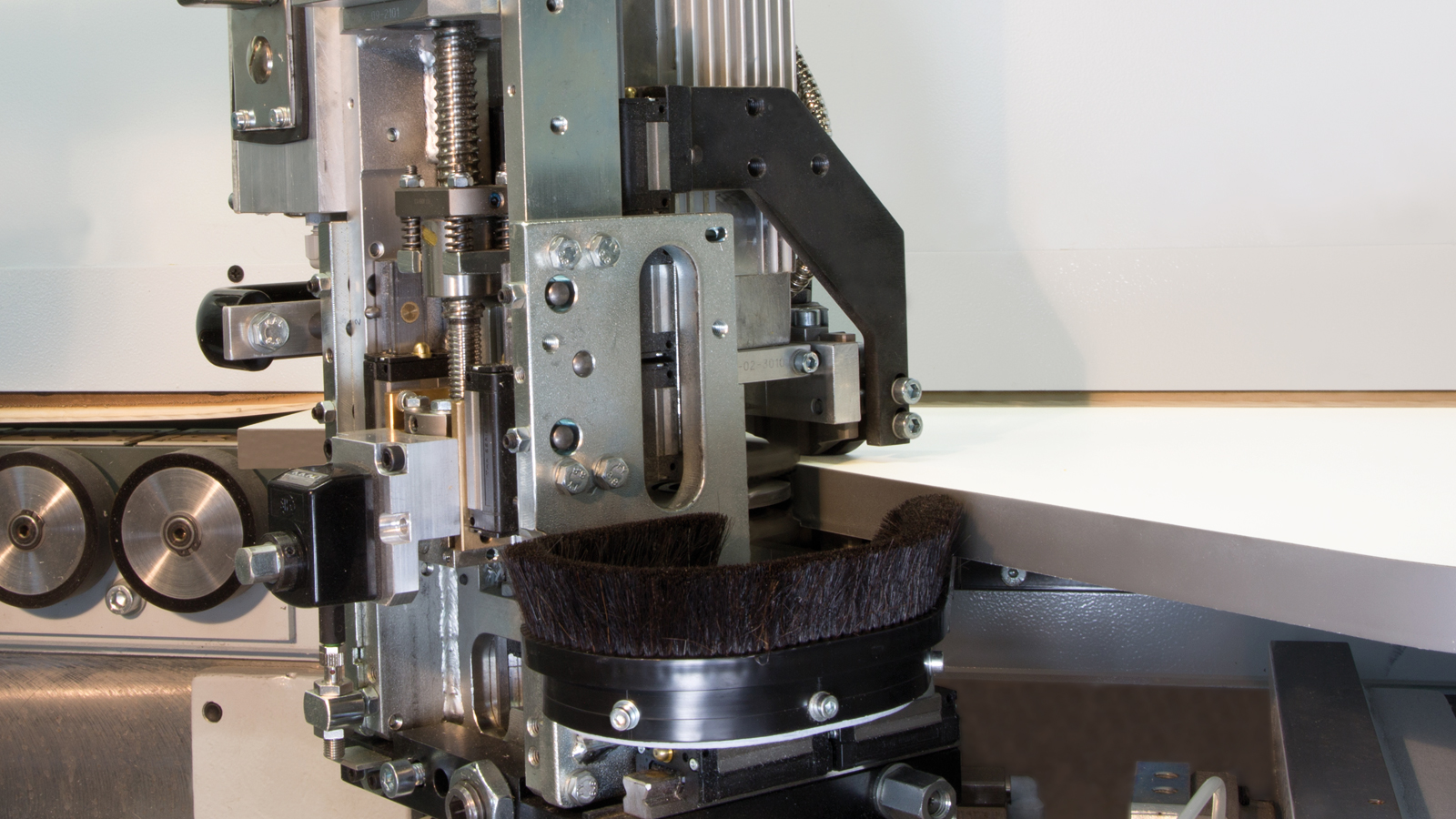

Contour trimming with no edge: Trimming of workpiece contours is CNC-controlled. Undercut trimming is possible

-

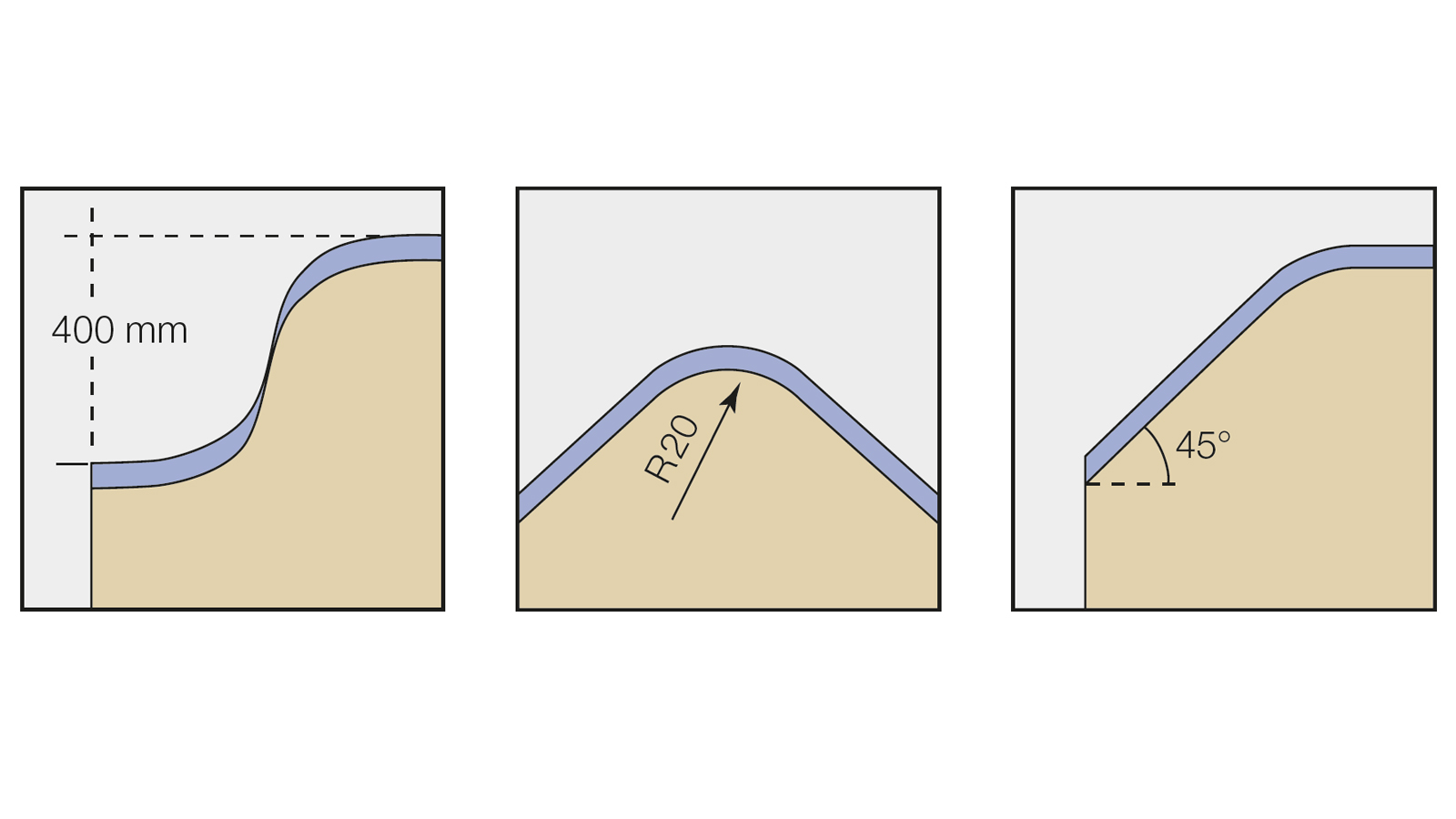

Contour trimming with edge banding: Following CNC-controlled trimming, plastic or veneer edges can be glued for many contours.

Maximum contour depth = 400 mm, maximum contour incline = 45°, minimum contour outer radius = 20 mm -

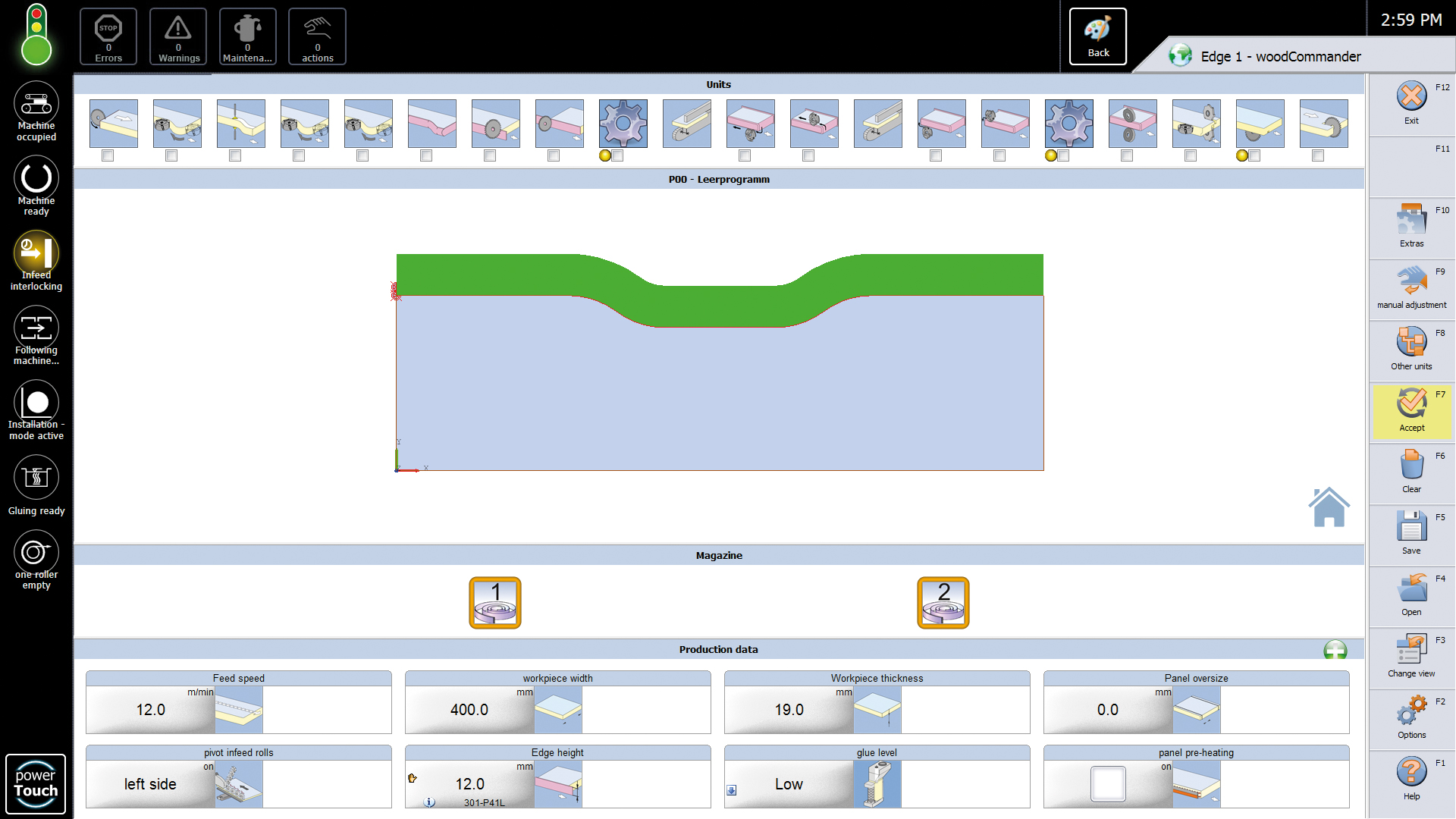

powerTouch control system with clear, user-friendly interface

-

Creation of contours using woodWOP

Technical Data

EDGETEQ S-810/CF | |

|---|---|

| Workpiece width [mm] (without back-pressure) | 150 + contour depth |

| Workpiece thickness [mm] | 12–40 |

| Workpiece length [mm] | min. 250 |

| Contour depth [mm] | max. 250 |

| Angle of inclination of contour | max. 45° |

| External radius of contour [mm] | min. 20 |

| Feed speed [m/min] | 6–30 |

(Previous product name: Shaped part throughfeed machines K 610/CF)

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

EDGETEQ S-810

The New Generation Of Molding Machine

Brochures