Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Product Optimization Technical Product Standardization

Product Optimization Technical Product Standardization

Working effectively despite product variety

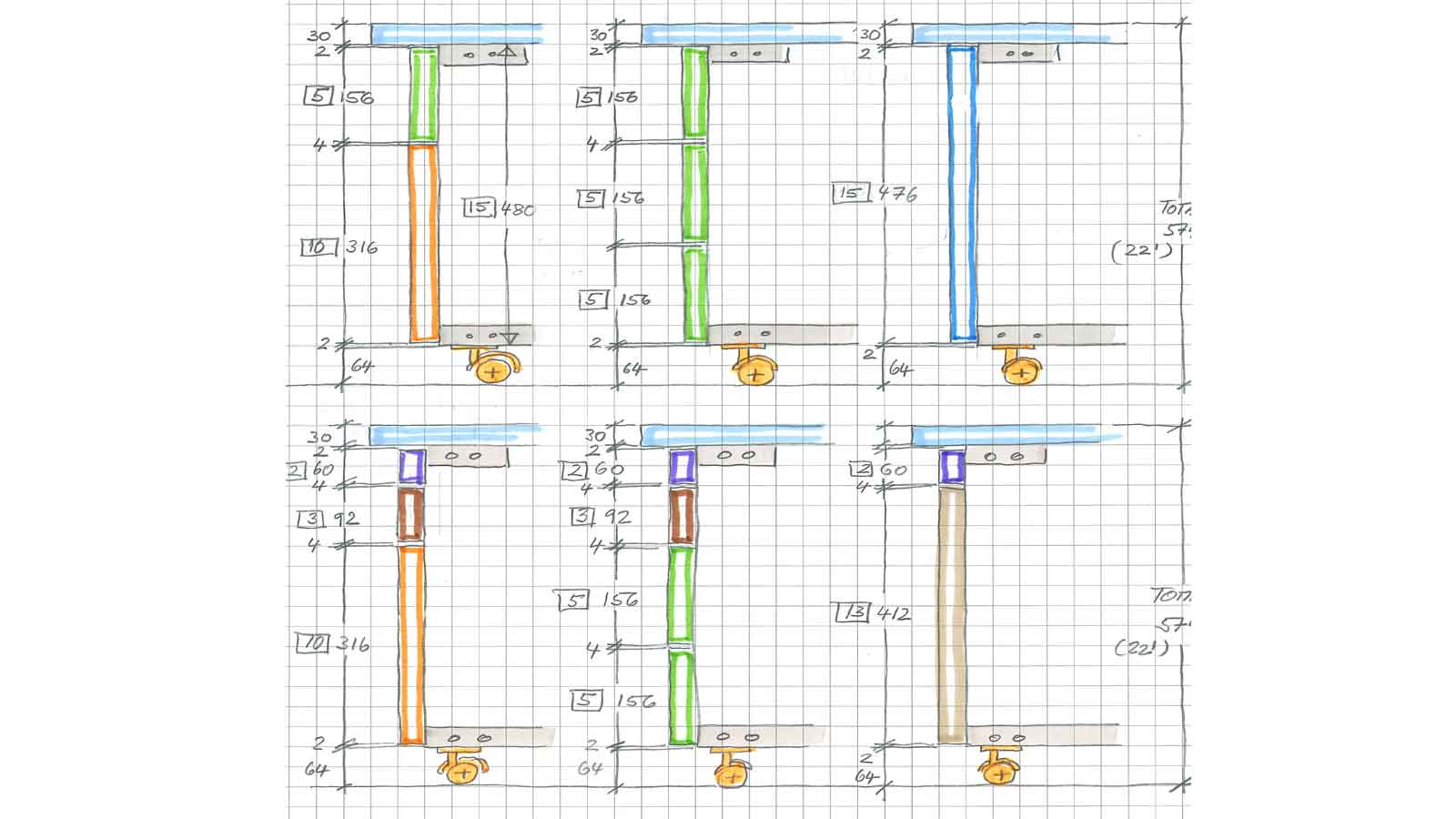

Over the years, the variety of models in many companies has increased significantly. This raises the pressure to keep track of your company's efficiency and inventories, despite the product variety. With our "Technical Product Standardization" consulting service, we help you define clear regulations for product design engineering. Using consistent standards and engineering principles, the part diversity and engineering variations are minimized and common product processing features are created. This leads to simplified production. And yet, the main priority is that clients and designers must not be restricted. Increase the efficiency of your entire organization by implementing an intelligent product design which ideally combines product demands and requirements.

Images

Features

-

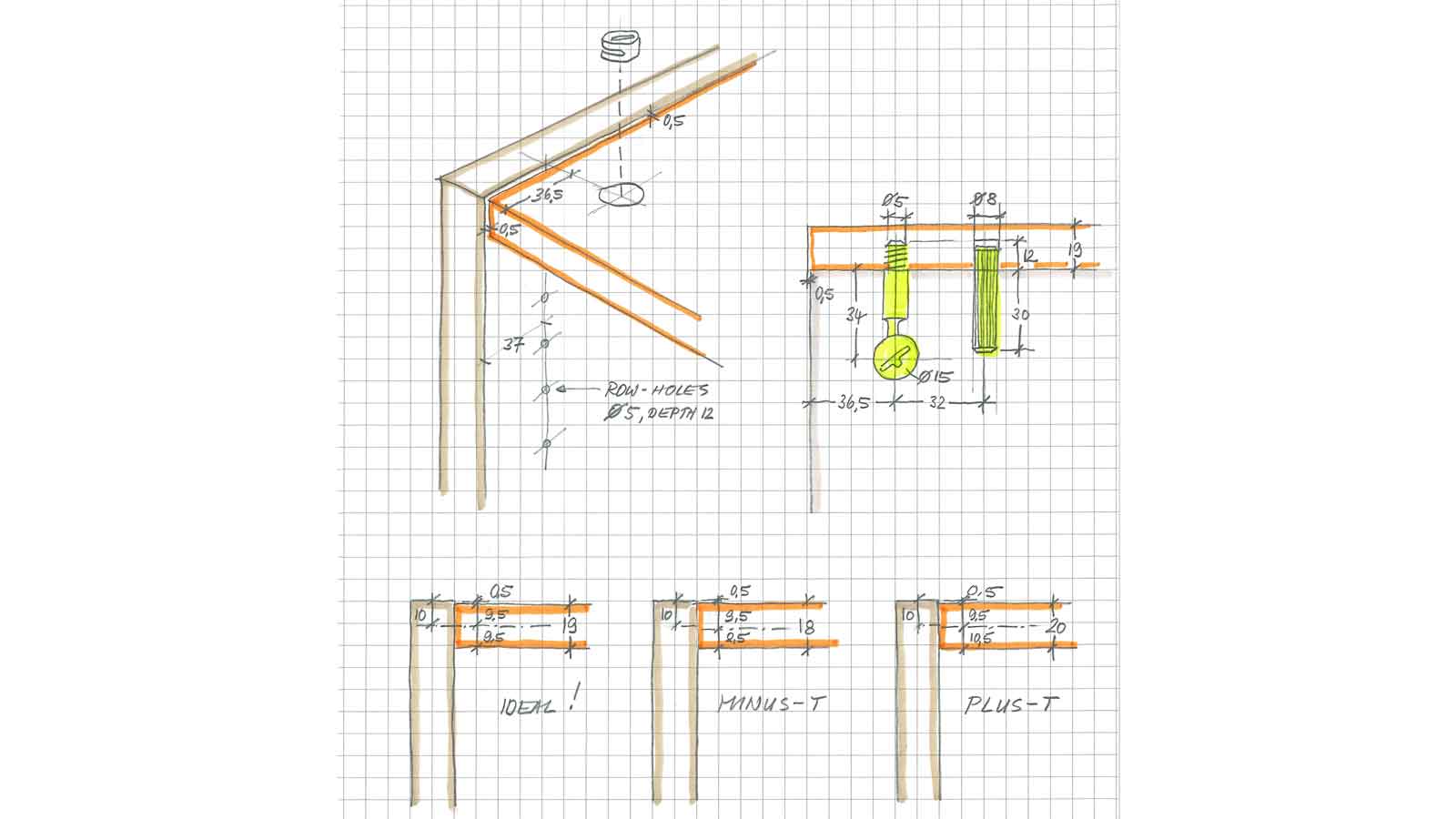

Developing optimized and standardized design engineering principles

-

Adjusting product design to the possibilities of manufacturing

-

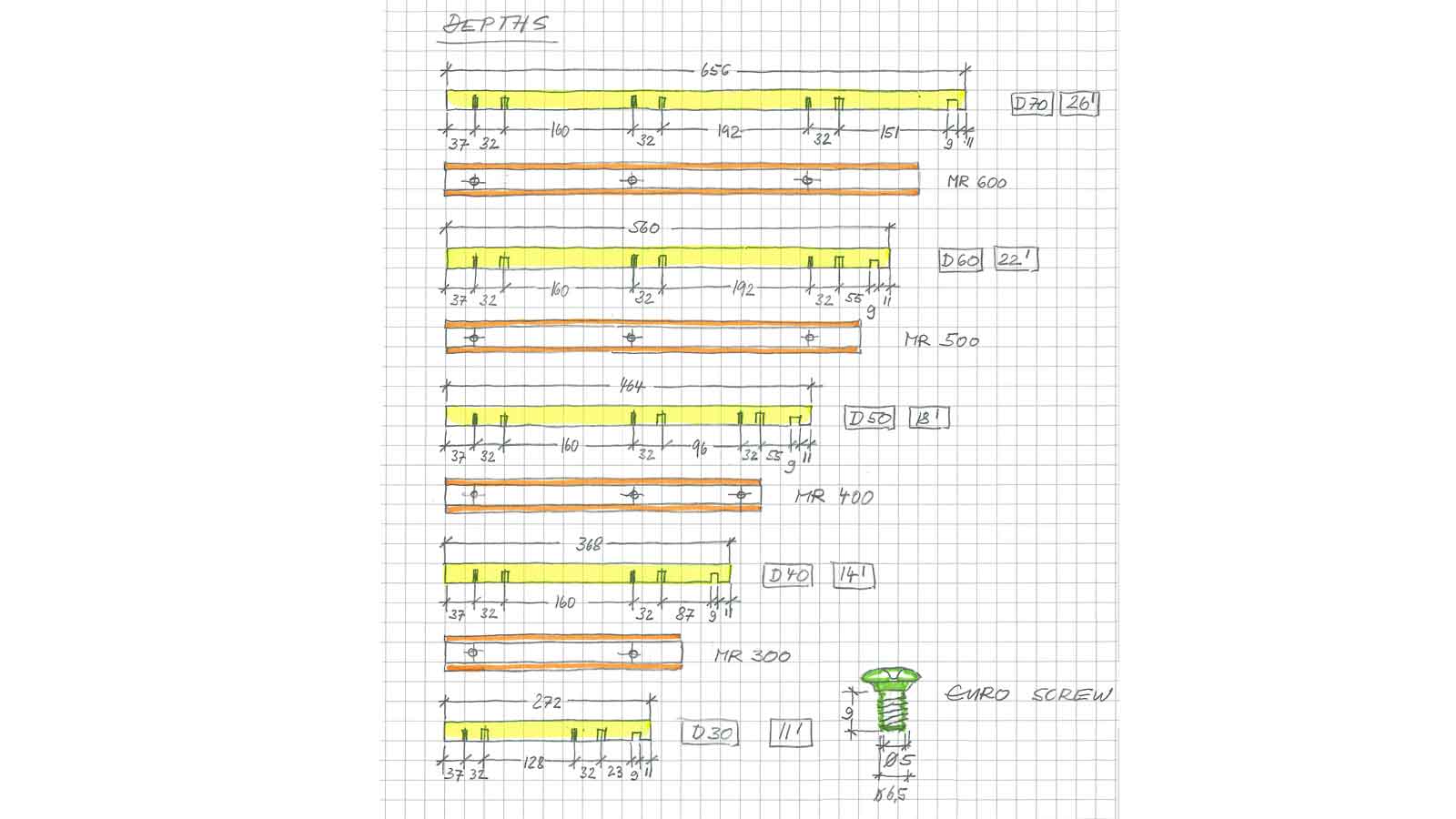

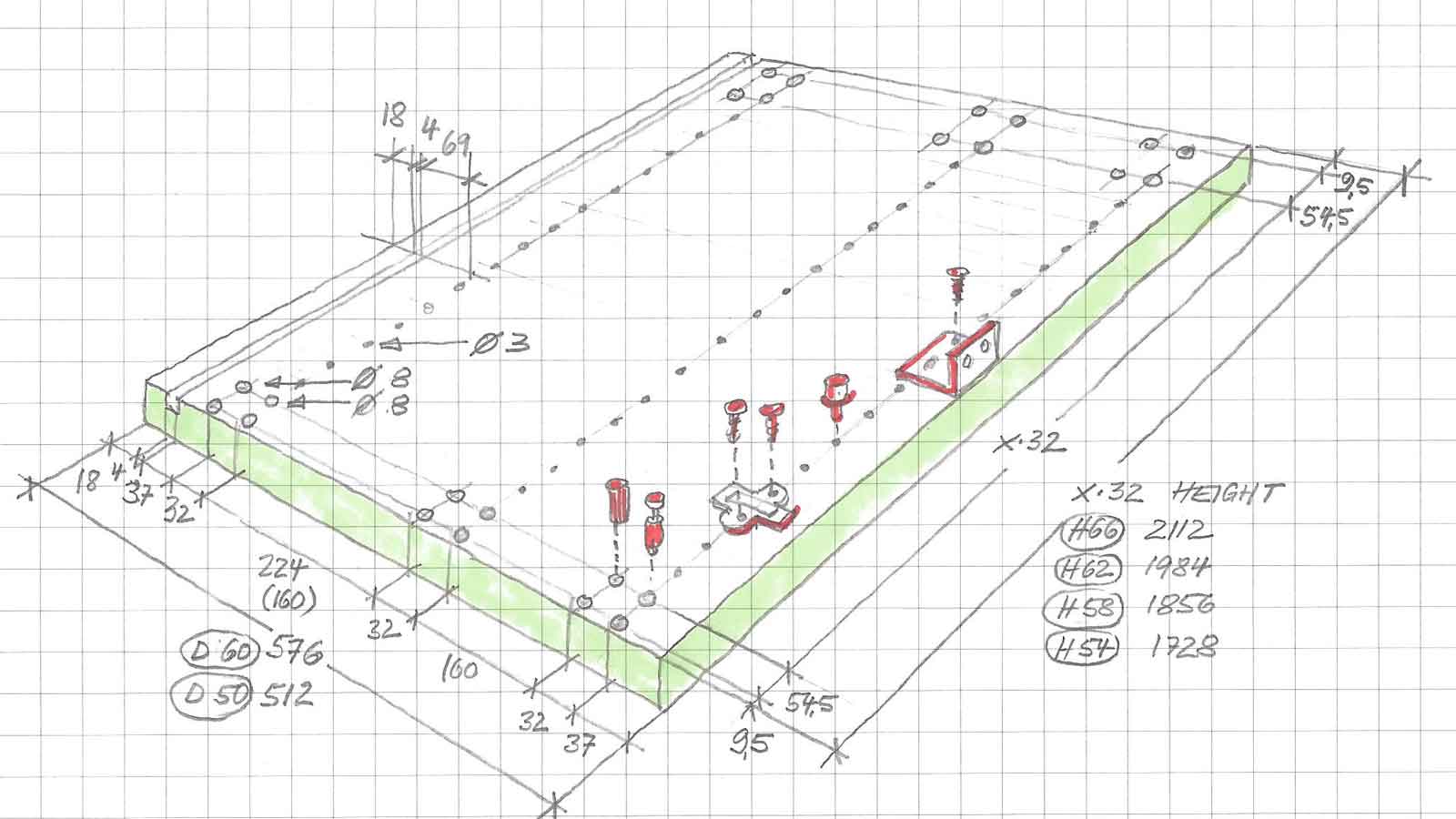

Defining grid dimensions and modules

-

Drafting design engineering documents for selected products

-

Standardizing fittings, connections and other materials

-

Reduction of machine setup times and lead times

Brochures