"Saudisation" leads to automation wave in the furniture industry

How manufacturer Al Joaib wants to reamin competitive

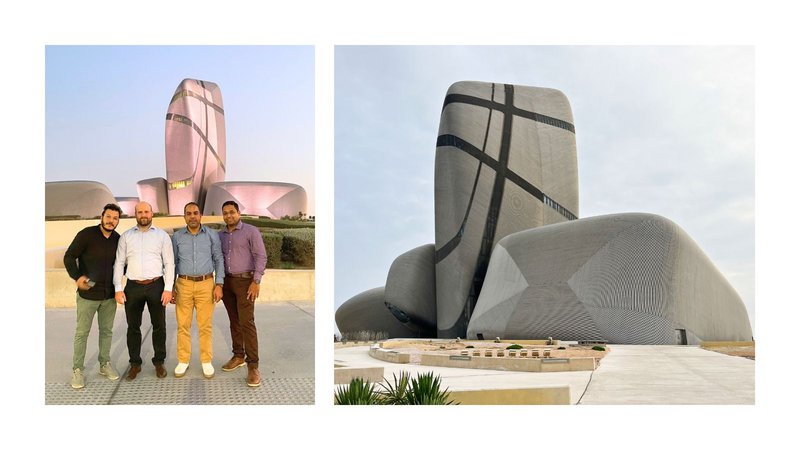

A visit to the impressive King Abdulaziz Center for World Culture followed by a Saudi barbecue contributed to the good working atmosphere and cooperation. Left: The project team (Image source: SCHULER Consulting), Right: Ihtra building (Source: sashapritchard, stock.adobe.com).

"My desire is to create a well-organized furniture factory that is able to achieve our production goals and meet the delivery times required by our customers. SCHULER Consulting provides us with the roadmap to success - the professional consulting online and especially on site as well as the know-how make the difference."

Ahsraf Anwar, Sales Manager (Al Joaib Furniture)

Author: Peter Hartmann, SCHULER Consulting

Published in HK magazine, issue 04, 2023, View online

The government of Saudi Arabia wants to develop the Kingdom's manufacturing sector from manual labour to a highly automated industry through "Saudisation". The core of the so-called "Saudisation" is to drastically increase the cost of work permits for foreign production workers so that companies hire more local skilled workers and invest in more efficient and automated manufacturing. In 2023, the five-year transition period for increasing the cost of foreign work permits will end. As a result, the competitiveness and profitability of many companies are now at stake. The Saudi furniture manufacturer Al Joaib decided to act and relies on the support of Schuler Consulting.

Al Joaib is a kitchen, bathroom and home furniture manufacturer specialising in the production, supply and installation of furniture for large new housing projects. The project business is specifically geared towards larger housing projects in the range of three to four-digit residential units. Al Joaib not only produces the furniture, but also carries out the assembly service on site. In addition, the manufacturer uses five per cent of the production capacity for the retail business and special orders in the high-end segment. Here, Al Joaib also cooperates with well-known European furniture manufacturers such as Bauformat Küchen & Noteborn.

The first goal in the optimisation project with Schuler Consulting was to save personnel. In addition, Al Joaib wants to optimise the use of resources in production and implement new state-of-the-art machinery in the factory. With a total of 82 employees (33 in production, 49 salaried), Al Joaib produces around 20,000 cabinets per year in single-shift operation. The main products are "Euro-style" kitchens, vanity units and built-in cupboards. Until a few years ago, the manufacturer was very well known for its kitchens with solid wood fronts. This trend has changed: Today, flat, melamine-coated fronts are in demand. Al Joaib enjoys a high reputation in its market segment in the Kingdom of Saudi Arabia, which is mainly based on good customer service and the punctual delivery of high-quality products.

Project stages: 1. increase productivity per employee

Al Joaib's assignment to Schuler Consulting was to develop a solid and future-proof production concept for manufacturing. The first step was not to increase capacity, but to increase productivity per worker, i.e. to achieve the same output with a minimised workforce. The goal was to reduce the workforce by 30 per cent. Through the comprehensive analysis of all production processes and the optimisations derived from it, the target value was exceeded: The planned value in the optimised production concept is now 37 per cent less staff.

The second step was to set up the production concept in a scalable way to enable future development steps. For example, Al Joaib can double the capacity in single-shift operation by investing step by step in known bottlenecks. Through these investments, Al Joaib can eliminate the bottlenecks in production and is able to achieve double the output with a minimal increase in the workforce.

2. optimisations in the area of cutting, edging, assembly

Major optimisations were made in the areas of cutting, edging, assembly and logistics. In the cutting department, parts handling was made more efficient: Fewer employees are now needed to stack the cut parts. In addition, a software-supported cutting optimisation with an import function from the work preparation should simplify and optimise the processes at the saw in the future.

In the edgebanding step, the investment in a new edgebander is necessary because the current edgebanders do not deliver satisfactory edgebanding quality, resulting in a lot of rework due to the removal of adhesive residues. In the current day-to-day business, Al Joaib uses a lot of resources to remove the adhesive residues. A new edgebander eliminates this rework and also minimises set-up times. In addition, a recirculation system is implemented, which increases the efficiency in parts handling.

The biggest structural change takes place in assembly: Here, a new assembly concept, a flow production with carcase press, is being implemented. Currently, the employees assemble the cabinets manually at different assembly stations in production. This is more flexible, but not efficient. In the new concept, the individual assembly steps in a flow production are arranged in optimised work areas along an assembly line. This includes separate pre-assembly for drawers and front fittings, as well as an optimised pre-insertion area, front and drawer assembly and attached packaging. Kitchen and bathroom cabinets are currently screwed together by hand during assembly. In future, the cabinets can be pressed together using a carcase press with a pure dowel connection. In future, there will also be a commissioning area for the carcase parts and fronts upstream of the assembly. Following assembly, the packaging has been designed in such a way that both assembled carcasses and flat packs can be efficiently packed.

In future, Al Joaib will consistently use a transport and buffer system in the form of roller conveyors for logistics in prefabrication. Currently, transport is still done manually with lift trucks. In addition, there is currently a lack of buffer spaces between the processes, which is problematic when it comes to balancing out production fluctuations. In the future, transport via roller conveyors should be easier and possible without auxiliary means. Newly arranged, fixed buffer locations allow, on the one hand, simpler intermediate storage of components between processes, and on the other hand, they can limit the production quantities in upstream processes and thus prevent overproduction. The new logistics concept simplifies the material flow in production so that the parts flow through production more efficiently and in a more regulated manner. This regulation enables better control of the production process and also creates more transparency about production performance.

3. flexible drilling concept for production

To improve flexibility, accuracy and quality in drilling, Al Joaib is investing in new drilling machines. Although the investment in these new machines requires a similarly high level of employee input, the decisive added value here lies in more flexible, efficient and qualitatively better component machining. In particular, the set-up processes are minimised considerably and the rework caused by inaccurate drilling is eliminated. Although Al Joaib operates in the project business, the production volumes do not justify the acquisition of a high-performance drilling machine. For this reason, and to maintain scalability, a more flexible drilling concept is used, which can efficiently handle the entire spectrum of parts. Flexible machining allows batch sizes to be minimised. This creates more flexibility in production planning and subsequent delivery.

Outlook

Al Joaib has used the state-driven modernisation offensive to set the course for the future. It remains to be seen whether other companies will be able to do the same. A wave of modernisation, digitalisation and automation is rolling towards Saudi Arabia that will not only produce winners. The message is clear: those who do not follow suit and modernise in order to be competitive will have to discontinue their business in the long term. The Managing Director, Mohammed Al Joaib, is satisfied with the results of the project and is pleased with the support of Schuler Consulting: "I am very happy that we were able to win SCHULER Consulting for the improvement of our furniture production. The expectations are high and we look forward to working together to achieve these goals. The project is part of our continuous development to increase customer satisfaction."

In the optimisation project with Al Joaib, the Schuler team uncovered a lot of potential. The furniture manufacturer wants to build on this foundation and push ahead with further projects together with Schuler, such as the digitalisation of production and work preparation. Among other things, the implementation of a new CAD/CAM system and the use of digital value stream optimisation by Schuler are on the list. The investments in the areas of digitalisation are paying off especially at the present time in Saudi Arabia. The state subsidises projects that fall under the heading of "Industry 4.0" with up to 75% from various funding sources.

So the cooperation between Al Joaib and Schuler Consulting continues, Sales Manager Ahsraf Anwar also confirms: "My wish is to create a well-organised furniture factory that is able to achieve our production targets and meet the delivery times demanded by our customers. Schuler Consulting provides us with the roadmap to success - the professional advice online and especially on site as well as the know-how make the decisive difference."

In addition to the many interesting insights into the production of Al Joaib and the various successful project stages, the project was marked by cultural highlights: A visit to the impressive King Abdulaziz Center for World Culture followed by a Saudi barbecue contributed to the good working atmosphere and cooperation.

About the author:

Peter Hartmann is a Senior Consultant at SCHULER Consulting and is active in Europe and South East Asia. He supports companies in the furniture and timber construction industries in setting up and implementing efficient, modern factories.

Back to List

SCHULER Consulting GmbH

+49 7445 830 791 00 info@schuler-consulting.com www.schuler-consulting.com Contact form