Due to the escalation of the trade war between China and the USA, Chinese furniture manufacturers and dealers are coming under pressure. The import duties imposed by the USA on its products put competitiveness and profitability at risk. A price increase for the end customer is only possible to a limited extent. On the other hand, paying the duties from the contribution margin or the mark-up will in the long run put companies in difficulty. The solution for many Chinese companies is therefore to outsource to furniture manufacturers in Southeast Asia. This process puts all parties under high cost pressure and poses a particular danger to producers. Just like everywhere else in the world, many producers in Southeast Asia are not fully aware of their operational cost structures. In most cases, the costs are not calculated on the basis of a direct product cost estimate, but using a classic mixed cost estimate. This method carries the risk that costs for individual products do not represent actual costs and can lead to massive losses in the case of larger orders.

It was precisely in this situation that the producer VersaLink found itself. The company has been manufacturing office furniture in the upmarket price segment near Kuala Lumpur, Malaysia, since 1991. The product portfolio ranges from classic serial furniture to furniture in the project business and individual customer pieces. In the past, distribution took place through the company's own brand, with the determination of sales prices being in the company's own hands. Since its listing on the stock exchange in September 2014, the company has been confronted with the situation of also acquiring new orders. This is now also being done by applying for what used to be Chinese projects where the buyers are now turning to South East Asian producers to supply their products. The focus is increasingly on the topic of design to cost where it is important for VersaLink to be sure about the detailed cost of products produced. In order to cope with this task, a workshop was started together with SCHULER Consulting to illuminate the cost structures and pricing within the company in order to optimize existing calculation models.

Cost engineering as the basis for the design to cost process has not yet been extensively applied in the wood and furniture industry, as it requires industry-specific process knowledge that is rarely combined with cost expertise, but it is precisely in the furniture industry that this knowledge of the industry, including the production processes carried out there, is essential. Only in this way is it possible to immerse oneself deeply in the production processes of the companies, to understand them and, if necessary, even to optimize them in further steps. Especially if the data quality and transparency of process parameters in companies are not secured or not available, they have to be processed accordingly, so that a subsequent allocation of the costs and the full cost transparency of the product becomes possible.

VersaLink and SCHULER Consulting can look back on many years of successful cooperation. In the past, many different production and IT development projects have been driven forward together. With the process knowledge from past projects, it was not a big challenge to immediately get into the Design to Cost topic in the workshop. Involved in the project were two VersaLink employees from the controlling department and the sales department, as well as the responsible persons from the different production areas. The calculation of the direct product cost calculation itself was supported by SCHULER's "Design-2-Cost" software.

For the workshop, two pieces of furniture from a current tender were used for the analysis. This is also a Chinese outsourcing project. When selecting the furniture, care was taken to ensure that a series and a customer-specific piece of furniture were considered.

Both furniture are office desks. The serial furniture was a pure panel furniture. The furniture is characterised by its simple appearance and consists of four large panel components, which are connected with the aid of dowels and eccentric connectors. The customized furniture was a combination of a steel underframe and a tabletop made of wood-based material. The steel underframe is designed in the form of a plug-in construction, whereby the horizontal trusses can be adapted to the customer's individual measurements and, consequently, the table tops must also be manufactured to the customer's individual requirements.

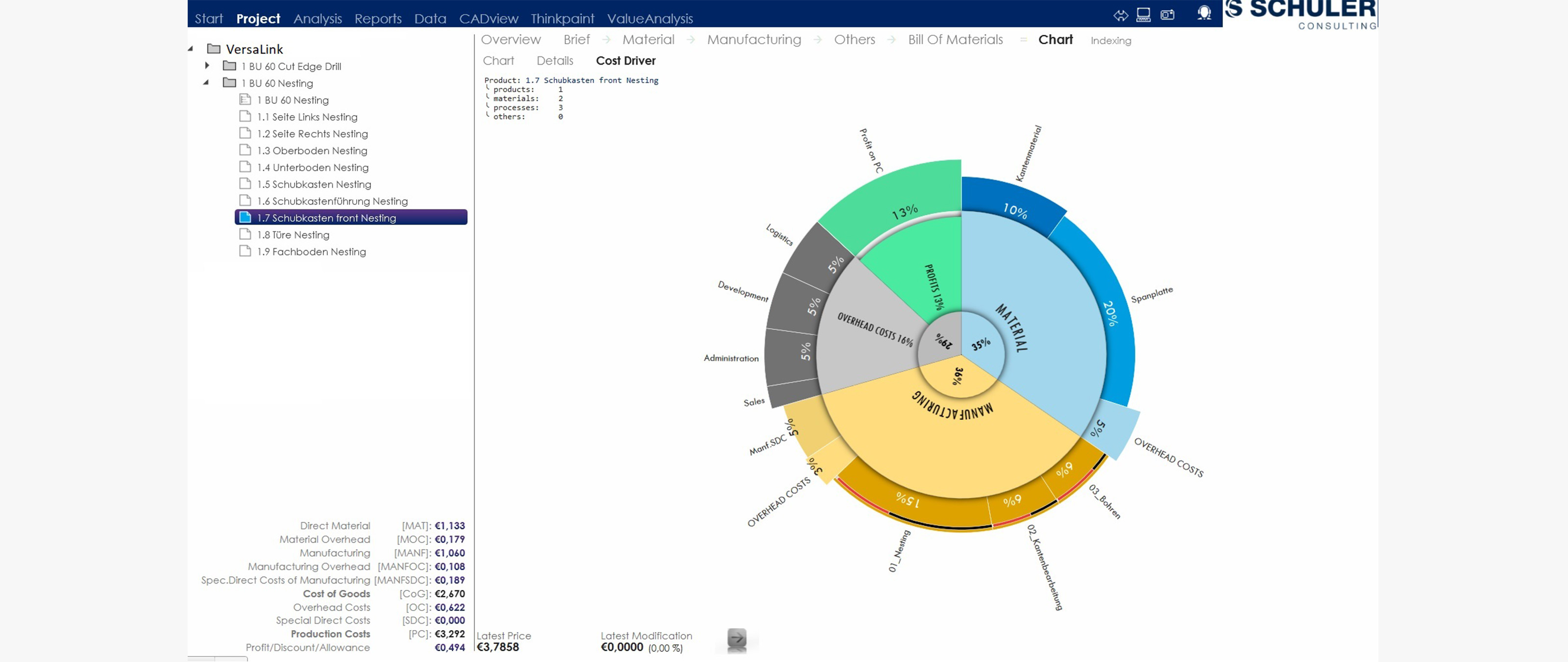

At the beginning of the design to cost analysis, the parts lists of the furniture with all self-produced and purchased items were listed and transferred to a standardized cost structure. Before this, however, a short digression on the subject of cost calculation was carried out. The basic topics of cost calculation itself and the cost model of the software solution used were explained. The company-specific prices for material and purchased parts were stored directly in one go. The processes and process times were then determined with the involvement of the production managers and assigned to the individual process steps. When calculating the material costs, both the employees with their different functions and salary classes were assigned to the machining processes and the machines and plants with their set-up times and the planned lot size were correctly assigned to the respective manufacturing processes.

In the course of the calculation, the detailed cost allocation quickly gave clarity in which areas VersaLink could improve their costing structure to make the whole process more efficient and even more accurate. As a result of this the project team immediately started to revise this refreshed costing scheme and to begin optimising the production process on the cost side in order to positively influence the cost price. Thanks to the new approach and process optimisation, the mass furniture requested for could now be offered at a much lower price than had previously been calculated. A transparent cost analysis and process optimization of the product made it possible to realize the expected lower sales price without reducing the profit margin and ensuring a good product is supplied at a good price to a happy customer.

By realizing the sales price at a constant margin, this project led to a better understanding of the actual cost allocation at VersaLink, which led to a significant increase in product cost transparency. This insight enables Controlling and Sales to allocate costs according to their origin and to set further incentives for cost savings as well as to check sales prices for validity. In particular, the approach of depicting furniture functions more cost-effectively and optimally simulating the production process will also lead to further design to cost projects at VersaLink. The increasing demand from VeraLink’s customers will therefore continue to lead to cost-optimised furniture exports from Kuala Lumpur in the future.

An article of the trade magazine HK, issue 3/2019. Here you can read the HK Magazine online.