Variant configuration in the kitchen industry

Today, when a customer wants to order his individual dream kitchen, he can design it quickly and easily at the POS. What processes lead to production after the order is received and turn his dream into reality usually remains hidden from him. The kitchen manufacturer, on the other hand, knows the processes that are necessary to realise the customer's wish. Variant configuration plays an important role. In his article for HK Magazine, Adrian Fried from SCHULER Consulting explains what needs to be taken into account here.

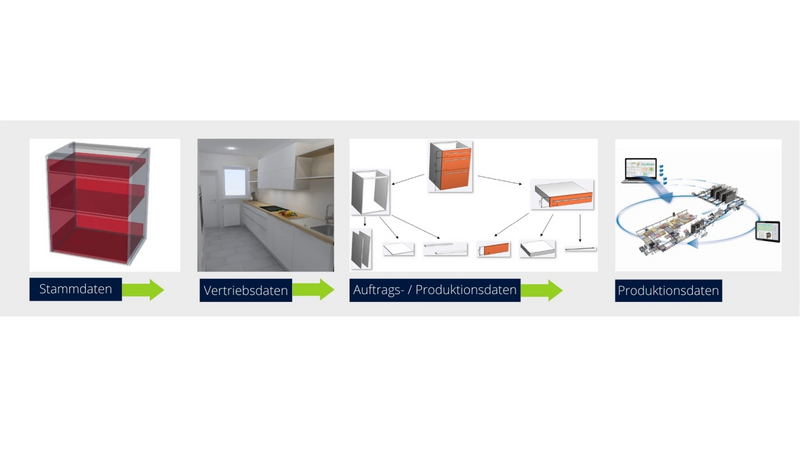

From order entry to production

The social megatrend towards individualisation is now making its way into all areas of life. More and more people want to express their personal taste within their own four walls. Whether a product can fulfil their individual wishes for function and appearance has a decisive influence on their buying behaviour. This trend in the market has thus also been reflected in the kitchen industry for some time, which meets this need for variation through highly flexible configuration.

While for the end consumer this variance is usually easy to recognise, a perceived matter of course and only a click away in the kitchen studio, the complexity usually lies in the economic organisation, production, logistics and assembly. In order to cope with this complexity, variant configuration is regarded as the defining tool for generating information and thus as the basis for efficient digital processes.

It takes on the task of assigning all the necessary features to predefined standardised products that meet the customer and information needs of the manufacturer. Any requirements can be entered via a set of rules running in the background. This ensures that all information recipients receive the data relevant to them. Once the configuration is complete and error-free, the foundation is laid for minimal but targeted human intervention with a high degree of automation.

Kitchen industry

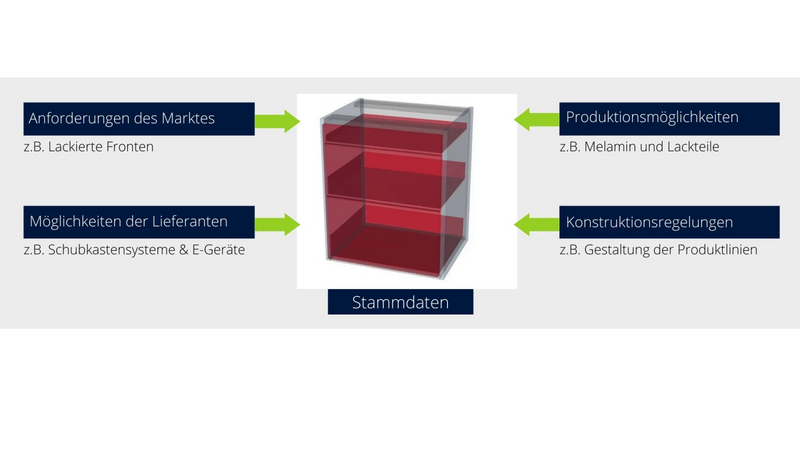

In the kitchen industry, four modules are needed for variant configuration: The customer-neutral core data or product catalogues, the point-of-sales software for customer-specific information, the variant configurator in the company, and production planning and control for generating all production-relevant characteristics. The basis is provided by the core data and product catalogues. Although the basic thesis is that the customer longs for complete customisation, rules of the game must be set for economic industrial production. These not only serve as a guide for the customer and as differentiation in the market, but also ensure that production receives an order intake tailored to its flexibility. In addition, a lean, systematically thought-out portfolio of basic products and characteristic values supports data maintenance.

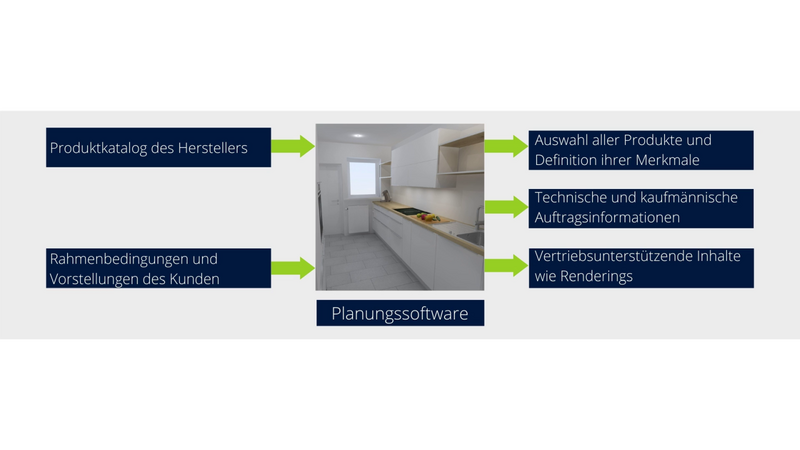

Software for planning

The planning software carries out the first of up to three steps for a fully comprehensive configuration and mainly serves to satisfy the customer's need: a visual representation of his dream kitchen. The basis and framework conditions for this are the manufacturer's product catalogues, the customer's exact spatial situation and his or her tastes and requirements for a kitchen.

Configuration

Configuration at this level works with few technical details and is reduced to the variance perceivable to the customer. This is usually defined by cabinet types, front design, colour, surface, electrical appliances and handles and determines the offer price accordingly. Features that may not be recorded, such as handles on fascia panels, must be passed on to the manufacturer via a comment on the product. However, this characteristic specification makes it possible to collect all the information necessary for sales and to create sales-supporting graphics such as renderings of the planned kitchen. Once the order has been accepted, the data is transferred to the manufacturer. The second stage of variant configuration aims to meet the manufacturer's information needs and delivers the sector-specific information to the ERP system, which is usually sector-neutral. The aim is to create reliable detailed information at component level for a wide range of company divisions from the rather sparse data of the sales department.

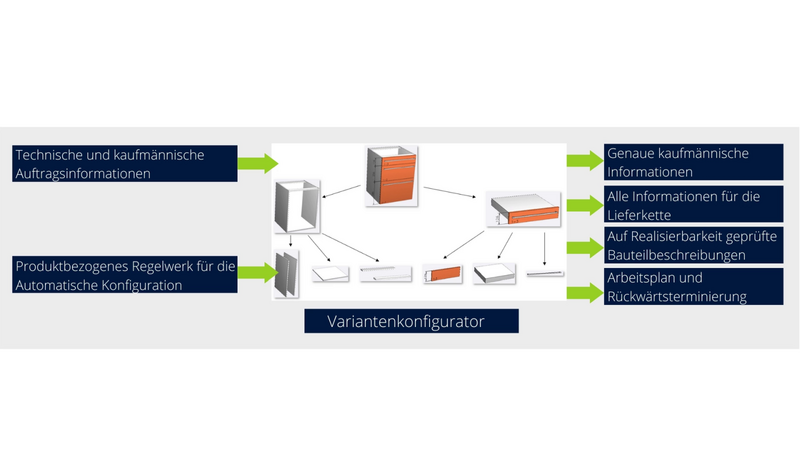

Variant configurator

The manufacturer's variant configurator works in two steps: If the sales order is imported in the first step, this data is checked for completeness or deviations, such as comments in positions. This is to ensure the data quality for the automatic BOM explosion and filling of all other characteristics relevant for the company. For this purpose, all products should not only be available as a data record, but also graphically rebuilt. This makes it possible to carry out collision tests, avoid arrangement errors and plan long parts such as worktops and plinths correctly and without errors.

Once this certainty is given, the second step, the BOM explosion of the products down to the component level, takes place. As in the planning software, this is supported by the master data and a set of rules stored in the configurator. As a result, production-neutral product and component descriptions should be available as data sets, graphics and neutral CNC programs. These data sets can be used to carry out the other company functions. Examples include rough capacity planning, a higher-level work plan, backward scheduling of production and material requirements. The ERP system takes over these data records and can carry out the more detailed planning activities based on characteristics.

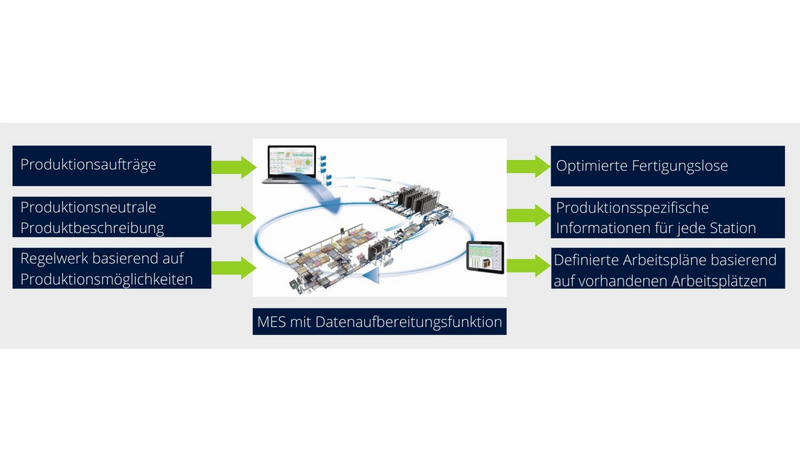

The third configuration level is production-related in the kitchen industry and resides in the industry-specific MES systems. The automatic configuration when importing orders from the ERP system aims to generate all the information necessary for production implementation. Again, an individual set of rules works in the background, configuring the necessary production information from the characteristics of the product description. If a company has different plants, the necessary information is thus only generated for the respective plant when an order is placed.

Production data preparation

The first step in production data preparation is the import of the data with renewed validation of the quality for production. If errors occur, the entire sales order should always be confirmed and blocked so that unfinished orders can be avoided in production. Once the order is finished and imported without errors, the production data is generated. This involves the three categories:

- Process values

- machine data and

- necessary automation information

All these data are generated for all components, assemblies, products and orders.

Process values are, for example, the concrete work plans and the detailed planning - that is, the scheduling of production. Machine data are cutting dimensions for saws, macros for edge banding machines or information for batch size 1 systems. The automation data, on the other hand, mainly includes geometry data and material properties in order to provide loading gantries, robots and sorting stores with all the information they need to run smoothly.

If a company has the goal of improving the information quality in an area or replacing an existing legacy system, the analysis should definitely consider the entire information chain from order entry to production. This enables the smooth integration of new elements such as an MES (Manufacturing Execution System) in the overall system. If such projects are one-off matters that occur repeatedly over a longer period of time, it can be helpful for the company to integrate an experienced service provider into the work. This can improve the quality and speed of the improvement process by specifically scrutinising the existing structures. Here, companies can not only benefit from the expert's knowledge, but also from a structured implementation of the optimisation measures, which are designed together with the employees on site.

Picture and text: Adrian Fried, SCHULER Consulting GmbH